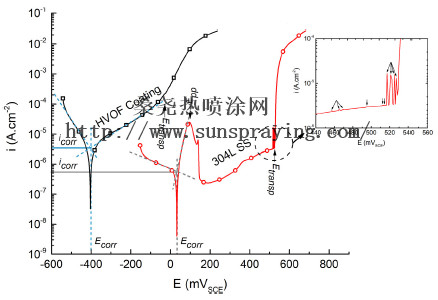

Most failures of engineering components originate from the degradation processes at the material's surface. The main causes that accelerate the deterioration of metallic material assets are generally attributed to the corrosion and wear. Good examples are turbines operating in marine environments where cavitation erosion is at the origin of fatigue, crack propagation and, therefore, related to severe material degradation leading to a drastic efficiency loss. Besides cavitation, chloride induced corrosion and other wear mechanisms contribute, in a lower or higher degree, to reduce the lifespan of the turbines and thus the materials selection must additionally consider these aspects. Among the commercially available alloys, stainless steels are well established materials for applications requiring high corrosion resistance and good mechanical properties at a relatively low cost. Austenitic stainless steels such as those of the 300 series are commonly used in several marine applications. However, some components operate in harsh conditions and hostile environments where, despite the excellent properties of austenitic stainless steels, severe degradation process occurs leading to premature failure and high cost replacement. This issue has motivated the development and the increasing use of engineered coatings for protection of stainless steel components. Surface engineering is widely used in different industrial sectors as a protective measure against a variety of physical and chemical degradations.In particular, thermal spray technologies that produce coatings with specific functionalities are among the most versatile choices to extend the service life of components with complex geometries. Wear- and corrosion-resistant coatings have therefore been used to protect the surfaces and for repair and restoration of components systematically subjected to severe degradation processes. Among the different thermal spraying routes, high-velocity oxygen fuel process (HVOF) provides an excellent combination of high velocities and relatively low temperatures, essential to produce dense coatings with high bond adhesion, high hardness, and low porosity. Because of these exciting characteristics, HVOF coatings have been successfully applied to coat the surface of turbines with complex shapes exposed to harsh environments. For instance, austenitic FeCrMnCoSi HVOF coatings (so-called CaviTec alloy) have been used to protect the surface of underwater engineering materials made with 304 SS, in which the cavitation erosion is the primary reason for component failure [18]. This is because the compositional selection of these coatings favors the minimization of the stacking fault energies aimed to ease phase transformation. By proper compositional selection, the structural transition from austenitic phase into martensite – transformation induced plasticity (TRIP) effect– absorbs energy from cavitation bubbles implosion, reducing the material removal caused by the resulting shockwaves and re-entrant micro-jets. This phase transformation also hardens the surface, which means low erosion rate and a longer incubation period .Correlation of low stacking fault energy of metastable austenitic matrix has also been used to improve the mechanical properties of a variety of high manganese steels with potential use in different applications. Regardless of the specific composition, the TRIP effect relies on the metastable austenite where ΔGaustenite➔martensite is negative of about −220 J/mol or less and the stacking fault energy is low (≤16 mJ/m2), which implies preferential strain-induced martensite formation. During deformation, carbon may diffuse to dislocations and stacking faults, locking or pinning them and, more important, rapid work hardening occurs due to the stress-induced transformation of austenite to martensite. It was found that friction-induced martensitic transformation of the thin layer of a Fe-Mn-C austenite steel was effective to increase the sliding wear resistance. The results from the pin-on-disc measurements of austenitic stainless steels also indicated a decrease in wear rate thanks to the combination of strain hardening and transformed martensite from the friction-induced austenite. All these trends point out that, besides high cavitation erosion resistance, the FeCrMnCoSi coatings may exhibit interesting sliding wear resistance but their performance under this condition are lacking.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|