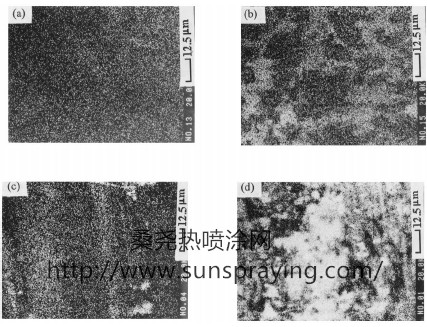

A number of laboratory studies have indicated that nickel aluminide alloys have significant potential in wear critical applications, especially in cavitation erosion and in sliding wear at temperatures of 400–650°C. However, these properties are poor in carbon steel, but it is considered that they can be improved by coating with inter metallic or ceramic material. In previous work, a Ni3Al-Cr7C3 composite coating was fabricated on commercial 1045 carbon steel by self-propagating high temperature synthesis (SHS) coating technology for improving the properties of the steel substrate. However, to our knowledge, there is little literature about the tribological properties of Ni3Al-Cr7C3 composite or its coating at room temperature under water lubrication. In the present paper, we will primarily investigate the tribological properties of Ni3Al-Cr7C3 composite coating at room temperature under water lubrication and attempt to explore the friction and wear mechanisms. The tribological properties of Ni3Al-Cr7C3 composite coating under water lubrication were examined by using a ball-on-disc reciprocating tribotester. The effects of load and sliding speed on wear rate of the coating were investigated. The worn surface of the coating was analyzed using electron probe microscopy analysis (EPMA) and X-ray photoelectron spectroscopy (XPS). The results show the friction coefficient of the coating is decreased under water lubrication. The wear rate of the coating linearly increases with the load. At high sliding speed, the wear rate of the coating is dramatically increased and a large amount of the counterpart material is transferred to the coating worn surface. The low friction of the coating under water lubrication is due to the oxidizing of the worn surface in the wear. The wear mechanism of the coating is plastic deformation at low normal load and sliding speed. However, the wear mechanism transforms to microfracture and microploughing at high load with low sliding speed, and oxidation wear at high sliding speed. It is concluded that the contribution of the sliding speed to an increase in the coating wear is larger than that of the normal load.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|