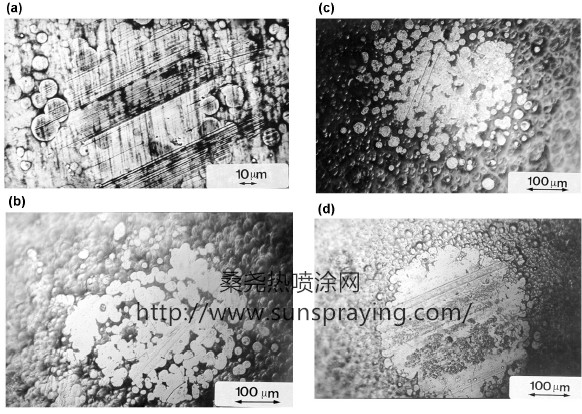

Most of the multilayered coatings have been produced by vacuum deposition techniques and as a consequence, the majority of studies dealing with the wear behaviour of multilayers are concerned with ceramic or ceramic/metallic multilayers produced in vacuum. However, much effort has been put into the development of the less expensive and more industrialised electrodeposition method lately (either a dual bath or a single bath technique with the aid of pulsed current), with results showing that the production of high-quality metallic multilayers is possible. The wear behaviour of these metallic multilayered coatings produced by the electrodeposition method has attracted the interest of a few workers, but nearly the entire number of investigations are con®ned to the study of unlubricated wear. Ruff and Wang studied the unlubricated sliding wear behaviour of Ni±Cu multilayered coatings on steel prepared by electrodeposition. They used a crossed-cylinder geometry and the counter material was AISI type 52100 steel. The composition-modulated coatings showed less wear than coatings of pure copper and nickel. The wear was found to be dependent on the wavelength (bilayer thickness) for the composition modulated coatings. In a recent publication, Zhang and Xue studied the effect of the thickness ratio of the individual layers that comprise the multilayered coating, as well as the effect of wavelength, on wear rate, for Cu±Ni multilayers produced by electrodeposition. The maximum wear resistance was observed for the multilayers with the minimum thickness of nickel layer (8 nm) and Cu/Ni thickness ratio 2:1. All the multilayered coatings showed better wear resistance than homogeneous coatings of Cu and Ni. The lubricated sliding wear behaviour of Ni±P±W multilayered alloy coatings sliding against hardened steel discs was studied, in a pinondisc set-up. The multilayered coatings had been deposited on mild steel pins by pulse plating and they consisted of ternary Ni±P±W layers of high and low Wcontent. The wavelengths studied were 6, 200 and 2000 nm and the total thickness of the coatings was 25 mm approximately. Using a range of normal loads between 2 and 110 N and a range of sliding speeds between 14 and 90 cm/s, the Stribeck curve of the system was constructed, indicating the various lubrication regimes. The wear mechanisms in each lubrication regime were studied and in mixed lubrication regime, the effect of normal load and sliding speed on wear volume and friction coefcient was also studied.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|