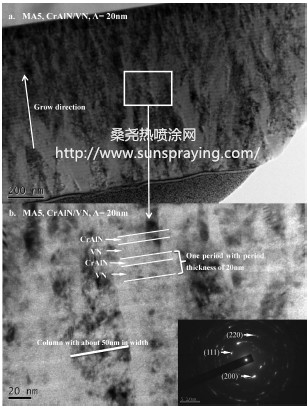

Recently, vanadium nitride (VN) has attracted increasing interests as VN is easily oxidized to form Magnéli-phase vanadium oxides have easy slipping shear planes and melt at approximately 685 ◦C thus becomes ‘lubricious’ under stress and temperature. Series of V-based hard coatings have been developed, such as (V, Ti) N, CrVN, CrAlVN composite coatings, AlN/VN and TiAlN/VN multilayer coatings with good mechanical and tribological properties. In TiAlN/VN multilayer coatings, melting of VOx at 700◦C gives rise to low friction coefficient of 0.18. In our previous research, CrN/VN multilayer coatings demonstrated low coefficient of friction (COF) of 0.21 due to formation of VOx during tribo-test at room temperature. CrAlN coatings have good oxidation resistance, anticorrosive and anti-adhesive properties, but inadequate tribological resistance hinders their applications in dry machining.Logically, the combination of CrAlN and VN should provide an alternative for a hard and lubricant coating for soft metals. In this study, CrAlN/VN multilayer coatings are deposited via magnetron sputtering to study the effect of the CrAlN/VN period thickness on the mechanical performance and tribological behavior at room temperature. At a proper period thickness, the coatings are of high hardness and low COF rendering low wear rate. Vanadium nitride (VN) is easily oxidized to form vanadium oxides and becomes lubricious under stress. CrAlN is hard thus CrAlN/VN multilayer coatings render both hardness and lubricious properties attractive in dry machining of soft metals. This study investigates the effect of multi-layering on the coating’s mechanical and tribological properties at room temperature. The CrAlN/VN multilayer coatings are deposited on cemented tungsten carbide and Si wafer (1 0 0) substrates in an in-line magnetron sputtering system. A period contains one layer of CrAlN plus one adjacent layer of VN. The period thickness varies roughly from 3 nm to 30 nm; the total number of the periods varies from 30 to 300. X-ray diffractometry, scanning electron microscopy, transmission electron microscopy, X-ray photoelectron spectroscopy and electron probe micro-analyzer are employed to characterize the microstructures and chemistry.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|