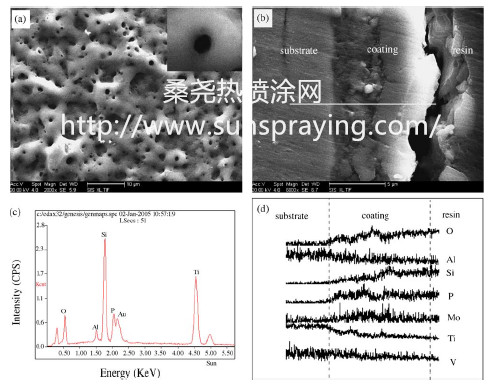

Surface modification, e.g. shot-peening and hard or soft coatings has been developed to improve thewear resistance properties and to enhance the ability of components to resist fretting damage. In recent years, a novel anodizing method enhanced by spark discharging, namely microarc oxidation (MAO), characterized by high productivity, economic efficiency and ecological friendly, especially, enabling to achieve thicker ceramic coatings of excellent properties: high hardness, good wear resistance and excellent bonding strength with the substrate, has been significantly focused on forming ceramic coatings on titanium alloys to improve corrosion and wear resistance.However, it should be mentioned that all the research work on wear resistance of microarc oxidation coatings formed on titaniumalloy are carried out under sliding wear mode. To our knowledge, no data can at present be available concerning the investigation on fretting behaviour of such coatings. Ceramic coatings were formed on Ti6Al4V alloy surface by microarc oxidation (MAO) in a Na2SiO3 system solution. Unlubricated, smear oil and oil bath lubricated fretting tests were performed on MAO coatings against 52100 steel on a fretting wear tester. Microstructural investigation of the worn surfaces was performed and the wear mechanisms were studied. The results show that the coatings are mainly composed of rutile and a small amount of anatase TiO2, both in nano grain structure. Friction coefficient of microarc oxidation coatings under oil bath lubrication was significantly reduced, favorable stable at 0.15, which indicates that the coatings with oil lubricated lowered the shear and adhesive stresses between contact surfaces, consequently alleviating the possibility of initiation and propagation of cracks in the inner layer of the coating or titanium alloy substrate.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|