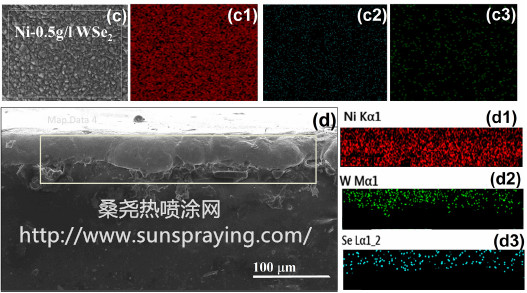

Metal dichalcogenide layered materials like MX2 (M=Mo, Nb, W, Ta; X=S, Se, Te) have attracted the worldwide researchers for their exciting self-lubricating behavior. They have structure similar to graphene. Their excellent low friction performance is usually associatedwith easy shearing of the weak interlayer bonds. Such extremely good lubricating action can function somewhat like an oil medium by the formation of a tribofilm between two mutually sliding surfaces. They display an extremely low friction due to the layered structures bonded by weak van der Waal's forces facilitating interplanar shear. It has been observed in literature on electrodeposited Ni based composite coatings that there are some successful studies on the codeposition of transition metal dichalcogenide into a nickel matrix, such as Ni-WS2, Ni-W-MoS2, Ni-P-MoS2, Ni-Co-MoS2, Ni-MoS2 coatings. Very few reports could successfully elaborate better lubrication behavior in inert atmosphere. But, in ambient atmosphere sulphide based transition materials, specifically MoS2 and WS2, become vulnerable due to their moisture sensitive tribological behavior unlike selenides based transition metals, such as WSe2 and MoSe2. So, sulphide based transition materials are comparatively less effective in humid environments as oxygen and water vapour could lead to the formation of oxides on the coating surfaces leading to an increase in coefficient of friction. In addition, sulphide based transition materials have reactive dangling bonds on the prismatic edges, which are vulnerable to oxide formation and consequently lead to the deterioration of the low friction property. For example, molybdenum disulphide (MoS2) has an extremely low COF (≤0.1) in vacuum and inert atmospheres, but increases to 0.3 to 0.5 in humid air. Moreover, increase in coefficient of friction of MoS2 based coatings in humid environment can be explained as the transformation of MoS2 to MoO3 resulting in interruption the layer movement. The present work investigates correlation between the structural and tribological behavior of pure Ni coating and Ni-WSe2 composite coatings at different WSe2 loading level (0, 0.1, 0.2, 0.5, 1 and 2 g/l). The developed coatings were characterized by X-ray diffraction technique (XRD), field emission scanning electron microscopy (FESEM) and energy dispersive spectroscopy (EDS) for phase, structure and compositional verifications, respectively. Structural and phase evolution of the coatings were correlated with roughness, microhardness and wear behavior. Characterization confirmed that beyond 0.5 g/l WSe2 content in the electrolyte, the composite coatings turned brittle and non-uniform with high surface roughness. The maximum hardness of 665 HV was observed in case of Ni-0.5 g/l WSe2 coating, whereas, the lowest average coefficient of friction of 0.068 was found in Ni-1 g/l WSe2 followed by 0.07 for Ni-0.5 g/l WSe2 coating. It was observed that Ni-0.5 g/l WSe2 coating possessed optimum mechanical properties and wear resistance.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|