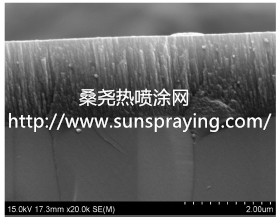

Al-Mg-B14-based boron-rich boride thin film coatings are becoming an attractive research subject because of their outstanding mechanical and electrical properties. These coatings have been successfully deposited on various substrates and demonstrated a wide range of promising applications. In particular, it has been shown that AlMgB14-TiB2 coatings with a nanocomposite microstructure can substantially reduce the friction coefficients of mechanical components and improve the operation efficiency of mechanical systems under the water eglycol boundary lubricated condition. The friction coefficient could drop to as low as 0.02 and the subsequent efficiency improvement could reach as much as 10%. A comprehensive study of the friction and wear mechanisms for these coatings suggested that boric acid (H3BO3), with a layered crystal structure similar to that of graphite and MoS2, thus acting as a self-lubricant, plays the primary role of greatly reducing the friction coefficient. This study also found TiB2 phase, rather than AlMgB14 phase, is the major source of boric acid. It is well established that boric acid is a reaction product of boron oxide and water molecules in a humid environment. However, the above conclusion is based on the XPS results obtained from bulk samples, while both the stoichiometry and microstructure may be changed in thin film form. In our recent work, we studied the surface hydration behaviors of the as-deposited and 700℃ annealed thin film coatings of AlMgB14, TiB2 and AlMgB14-TiB2 We found an atase TiO2 is actually a key factor controlling the boric acid formation at the surface of these boride coatings. Al-Mg-Ti-B coatings were deposited onto as-received bearing steels at 350 ℃ by direct current magnetron sputtering. The target was hot-pressed stoichiometric AlMgB14-TiB2 compound. Prior to deposition, the steel substrates were sequentially cleaned ultrasonically by acetone and alcohol, and then further cleaned by Ar+ ion etching in vacuum chamber to remove the surface contamination. Al-Mg-Ti-B coatings were also deposited on (110) Si substrates at 350 ℃ for X-ray diffraction (XRD) characterization and cross-sectional Scanning Electron Microscopy observation. X-ray Photoelectron Spectroscopy was used to determine the atomic concentration of the Al-Mg-Ti-B coating deposited on (110) Si substrates. After deposition, one set of coated samples was subjected to UV irradiation for 8 h, and another set of coated samples untreated by UV irradiation was used as a reference for comparison.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|