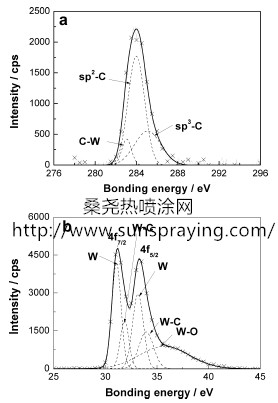

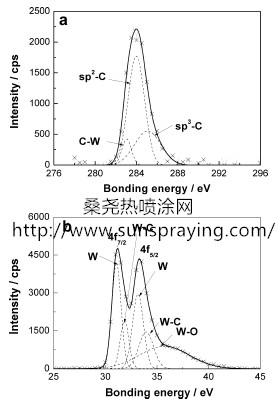

Amongst the studied doping elements, tungsten is one of the fascinating doping elements for it can greatly reduce the structural differences at the coating/substrate interface and the internal stress in the DLC coatings, improve the thermal stability, hardness, coating-substrate adhesion, and wear resistance of the DLC coatings. So the improvement of the DLC coatings by W doping has attracted much attention, but the most research emphasis is attached to the tribological performance of W-doped DLC coatings under dry friction. However, the improvement of mechanical parts only by the DLC coatings is not enough under the severe service conditions. The DLC-coated parts are usually required to service under oil lubrication in order to obtain a satisfactory wear resistance and service life, but the influence of W content on the tribological behavior of the DLC coatings under oil lubrication has not been completely understood. The tribological performance of a part is related to both the surface materials of the counterparts and the service conditions. Under different friction conditions, the variation of the wear rates of the DLC coatings with W content can exhibit different behavior. So, the study of the tribological performance of the DLC coatings under the possible service conditions is necessary for the application of the DLC coatings. The influence on tungsten content on the structure, mechanical properties and tribological performance of W-doped diamond-like carbon (DLC) coatings was studied by X-ray photoelectron spectroscopy, nano indentation, scratch test, and ball-on-disk friction test. It was found that with increasing W content, the content of WC and free W in the coatings is increased while the content of sp3-C in the coatings is decreased. The effect of W content on the hardness and elastic modulus of the coatings is indistinctive, but there exists the highest critical load of scratch test of above 100 N when W content is 3.08 at.%. With the increase of W content, the friction coefficients of W-doped DLC coatings under dry friction conditions are increased while the friction coefficients of W-doped DLC coatings under polyalpha olefin (PAO) lubrication are decreased. With the increase of W content, the wear rates of the DLC-coated samples under dry friction conditions show a minimum value; under pure PAO lubrication, the influence of W content on the wear rates of the DLC-coated samples is indistinctive when the W content is below 10.73 at.% while the wear rates are increased with increasing W content from 10.73 at.% to 24.09 at.%; when lubricated by PAO + thio phosphoric acid amine (T307) salt, the samples coated with the undoped DLC or the W-doped DLC with high W content exhibit low wear rates.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|