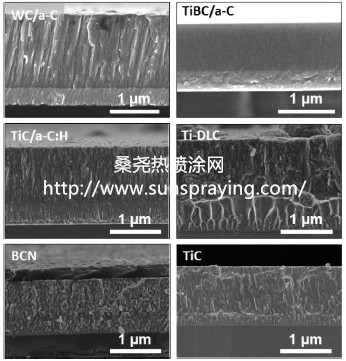

Hard carbon coatings display a number of highly interesting material properties that have led to their use in a wide range of tribological applications. Their high hardness, corrosion and wear resistance, and their low friction allow using them as protective layers on bearings, gears and engine components. In many aspects, the demands on coatings for machine components are tougher than those for cutting tools. The expected lifetime is very long, the coating costs must normally be low compared to component costs, the substrate hardness is rather low, failure or detachment of the coating can lead to catastrophic failure of the whole system and usually the contact is lubricated. For the last three decades, solid lubrication by thin coatings has mainly been used to stretch the limits of classical oils and/or fluid-base lubricants. Coating of the working surface with diamond-like carbon (DLC) films gives similar frictional properties and excellent protection against transfer of counter material to the working surface, even in the case of base oil without any additives. DLC is an amorphous carbon (a-C) or hydrogenated amorphous carbon (a-C:H) film material with a high fraction of metastable sp3 carbon bonding. Among different categories, doped and alloyed-DLC have the capacity to meet the increasingly stringent application requirements of advanced mechanical systems. Although enhancement of the hardness is in principle desired the generation of internal compressive stress, particularly in coatings with high sp3/sp2 ratios, favors the film delamination. The accumulation of compressive stresses in DLC films has been currently overcome by doping with metallic elements or using gradient functional under layers. New elements incorporated into a-C(H) coatings can either be diluted in the matrix, and a new single phase coating is produced, or be present as a second separate phase modulated in the nanometer scale to form multilayers or nanocomposites. Doped-DLC (with metals like Ti, Ta, Nb, Cr, etc. or nonmetals like B, N, Si or F) belongs to the first family while metal carbide (MeC) nanocrystals dispersed in a-C(H) matrixes are good examples of the second one. This generation of multi component nanocomposite coatings opens new possibilities of property improvement by appropriate control of their composition and structure at the nanoscale. Boron/carbon/nitrogen (BCN) compounds based on the graphite network are one of the carbon alloys and a kind of hybrids of graphite and hexagonal boron nitride (h-BN). Ternary BCN films, although softer than BxC compounds, combine a good friction coefficient, adhesion and wear resistance. Moreover, increased thermal stability over a-C and a-CN up to 800 °C has been demonstrated. The use of carbon-based coatings (hydrogenated and non-hydrogenated DLC, doped and alloyed-DLC) is of wide interest due to its applications in mechanical components submitted to friction and wear including sliding parts in automotive engines. A tribological comparative analysis using a reciprocating (SRV) tester in lubricated and unlubricated conditions with a 4-stroke motor oil has been carried out on six currently relevant state-of-theart coatings (namely WC/a-C, TiBC/a-C and TiC/a-C:H nanocomposites, Ti-doped DLC, BCN film and a crystalline monolithic TiC film as reference). The quantification of the fraction of the sp2-bonded matrix has been done by fitting of C 1s XPS peak and the mechanical properties evaluated by nano indentation. The comparative analysis has allowed us to identify the capabilities of each system depending on the testing conditions and the possible synergies as a function of the chemical composition and film nature. Under lubricated harsh conditions (max. contact pressure 1.7 GPa) only coatings displaying hardness superior to 20 GPa could stand the sliding motion without failure. At lower contact pressures, a significant fraction of sp2 carbon (≥75%) is advantageous for reducing wear in boundary lubrication. WC/a-C, BCN and Ti-DLC films showed the best tribological response in dry sliding conditions. This fundamental information would be of relevance for assisting engineers in selecting best partnership for lubrication systems.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|