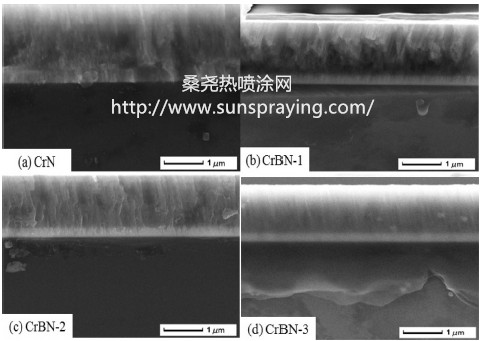

In comparison to TiN coatings, CrN coatings exhibit superior cor-rosion and oxidation resistance and lower internal stress.Wang et al. have studied and compared the tribological prop-erties among CrN, TiCN and TiAlN coatings sliding against SiC ballsin water, and indicated that CrN coatings possessed the best fric-tion and wear ability with the lowest friction coefficient value of 0.076. CrN coatings were also reported to exhibit superior corro-sion resistance as compared with TiN, TiAlN and a-C:H coatings due to the formation of beneficial tribochemical product (Cr2O3)[24]. Similar structure to Ti-B-N coatings, Cr-B-N coatings could bedeemed to present superior mechanical and tribological properties. Zhang et al. [25] reported that the mechanical and wear resistance properties of Cr-B-N coatings were superior to those of CrN coat-ings. Cheng et al. [26] indicated that the microstructure of Cr-B-N coatings changed from columnar to nano composte structure con-sisted of CrN nanograins and a-BN phase as the N2gas flow ration in creased, and the fracture toughness and resistance against elastic strain to failure of coatings effectively increased simul taneously. Actually, the microstructure and mechanical properties of Cr-B-N coatings are strongly influenced by their boron concentration.However, the mechanical and tribological properties of CrBN coat-ings with low boron content in water lubrication have not been reported systematically. tCr-B-N coatings with different boron contents were deposited on Si(1 0 0) wafers and 316 L stainless steels using unbalanced magnetron sputtering system by way of adjusting the CrB2target currents .The microstructure and mechanical properties of Cr-B-N coatings were investigated by X-ray diffraction(XRD), X-ray photoelectron spectroscopy (XPS), white light interferometric three dimensional profilome-ter and nano-indentation tester, respectively. The tribological properties of Cr-B-N/SiC tribopairs in water were studied using ball-on-disk tribometer. The results showed that the Cr-B-N coatings showed a finenano composite structure consisted of CrN nano grains and amorphous BN phase regardless of boron con-tents, and the typical columnar structure became featureless with increasing the CrB2target current. The hardness and reduced elastic modulus first increased to 28.9 GPa and 330 GPa at the CrB2target current of 2 A, and then decreased gradually with further increasing the CrB2target current to 4 A. As compared with the CrN/SiC tribopairs, the lowest friction coefficient of Cr-B-N/SiC ball tribopairs in water was 0.15,and the wear resistance of Cr-B-N coatings was effectively enhanced.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|