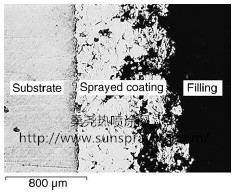

It is common to use thermal sprayed technology to prepare a hard coating on steel to improve the surface hardness and increase its wear-resistance. But a hard surface can accelerate the wear of the counterpart for rubbing-pairs, being ineffective for those rubbing-pairs under boundary lubrication, such as cylinder liner-piston ring, oil nozzle, ball bearings. Under these conditions, it is useful to produce a solid lubrication coating on the frictional surface. Some researchers have utilized thermal sprayed technology to prepare friction-reduced coatings of molybdenum disulfide and molybdenumbase alloy and achieved good results. Iron sulfide (FeS) is an excellent solid lubricant, possesses a close-packed hexagonal crystal structure and is effective in friction–reduction. An FeS coating is a very important component of solid lubrication coatings. Some studies on FeS coatings prepared by chemical heat treatment have been completed in detail, but the studies of FeS coatings prepared by thermal spray technology have not been reported in the literature. In this paper, the authors prepared three FeS coatings with different thicknesses by plasma sprayed technology, and then investigated their characterization and tribological properties. Plasma sprayed technology has been utilized to prepare solid lubrication FeS coatings with thicknesses of 0.3 mm, 0.8 mm and 1.5 mm. Their tribological properties were comparatively investigated under oil lubrication. An SEM equipped with EDS, and XRD were employed to analyze the surface and worn scar morphologies of the coatings, as well as the surface phase structures. A scratch testing machine was utilized to measure the bond strength between substrate and coating. The results showed that the tribological properties of the sprayed FeS coatings were superior to the original 1045 steel. The 0.8 mm thick coating possessed the best tribological properties. The differences in tribological properties of the three coatings were determined by the differences of their thickness and structure.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|