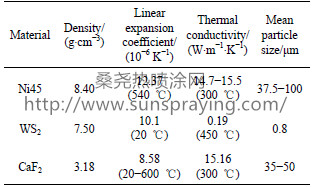

Solid lubricant coatings and powders are typically employed in extreme environment for providing high temperature lubrication. Conventional solid lubricants, graphite and transition metal disulfides such as MoS2, WS2 and TaS2, are widely used in metal forming and mechanically-driven devices. Due to the oxide formation, the lubrication capability of MoS2 coating breaks down at elevated temperature (300℃) and in humid atmosphere. It has been found that the friction behavior of tungsten disulphide (WS2) remains stable up to 450 ℃ in air. To widen operating temperature range of lubricating coating, one approach is to combine low temperature and high temperature lubricant materials into a composite structure. Alkali fluorides (CaF2, BaF2, LiF2) are alternative choices for their low shear strength and stable thermophysical and thermochemical properties at elevated temperature. The calcium fluoride (CaF2) is reported to exhibit effective self-lubrication properties in a wide temperature range when being applied as either bonded thin surface film or incorporated self-lubrication component in a metal matrix composite. When the temperature rises, it undergoes the brittle to ductile transformation, forming a fully ductile phase with very low shear strength. JOHN et al synthesized a composite coating of CaF2 and WS2 via pulsed laser deposition on a steel substrate, and CaSO4 films formed by the chemical interaction between CaF2 and WS2 at 500 ℃, which performed better than the coating including either CaF2 or WS2. In earlier studies, various attempts have been made to enhance the wear life of transition metal disulfides coatings by adding small amount of metals such as nickel, chrome or cobalt. It has been confirmed that partially metallurgical bonding between the substrate and the coating could improve the adhesion. So by combining of submicron WS2 and CaF2 powders with Ni-based alloy in a certain ratio, a self-lubricating composite coating would be produced, which provides lubrication over a wide temperature range. Amongst coating techniques, thermal spraying and laser cladding have been recently developed for producing metal matrix lubricant composite coatings. Self-lubricating composites doped with solid lubricants of CaF2/BaF2 eutectic and silver in a metal-bonded chromium carbide (Cr3C2) matrix have been developed by plasma spraying and laser surface cladding. WANG et al synthesized submicron WS2 and CaF2 powders with Ni-based alloy by Nd:YAG laser cladding, and achieved good results. But the temperature is too high to suit die surface application in these processes. Because of the chemical characteristics of lubricant WS2, i.e., low decomposition temperature of 510 ℃ and low oxidation temperature of 539 ℃, high velocity oxygen fuel(HVOF) spraying is considered a competitive method to produce high-quality coating. By burning high flow rate hydrocarbon gas in oxygen, the spray coating devices are designed to achieve supersonic expansion of the burning gas, and the gas exit velocity is so high (above 1 000 m/s) that spraying particles are shot onto substrate to form a dense coating with high adhesion strength.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|