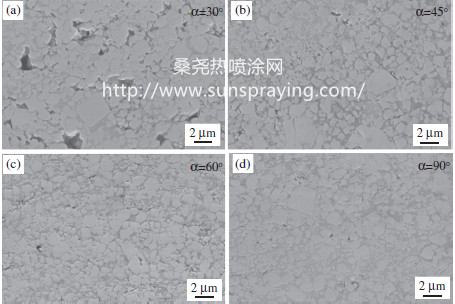

Note that, for practical applications, the coating performance should be a direct criterion to assess the applicability of these coatings. However, coating performance is not fully explored in relation to the spray angle even though the degradation in off-angle sprayed coating features and characteristics are thought to be detrimental to the final performance. In this aspect, the porosity, hardness and toughness etc. should be concerned and understood as a sum of surface integrity parameters that have a combined effect on the high performance of components. Up to date, wear resistance has been evaluated for the feasibility of off-angle spraying in few publications. Despite the reduced hardness and compressive residual stress of off-angle sprayed coatings, Strock et al. firstly reported an unexpected wear resistance enhancement for off-angle HVOF sprayed WC-CoCr coatings in comparison with that of normal angle sprayed coatings during dry fretting wear test against NiAl-bronze alloy or AISI 4340 steel wear pair under a load of 1.8 MPa and a frequency of 300 Hz for 8 h or 16 h. The exceptionalwear response was attributed tomore uniformly distribution of phases across the coating surface at off-angle spraying, and the enhanced wear resistance of off-angle sprayed coatings also caused greater wear of the wear pairs. More recently, Houdkova et al. confirmed poorer wear behavior of off-angle HVOF sprayed hardmetal coatings evaluated by a dry sand/ rubber wheel test under low-stress condition with a load of 22 N and a sliding distance of 1.436 m, where significant reduction in wear resistancewas observed at less than 45° forWC-17Co coatings and less than 60° for Cr3C2-NiCr coatings, with a high wear rate of nearly doubled for WC-Co and over doubled for Cr3C2-NiCr as comparing the 30° sprayed coating to that of normal angle. Recalculating the reported data, the specific wear rate could be estimated to within a range of 10−4–10−5 mm3/Nm. The authors recommended a maximum 30° diversion fromthe normal angle forWC-Co and 15° diversion for Cr3C2-NiCr coatings, i.e. the critical spray angle is 60° for WC-Co coatings and 75° for Cr3C2-NiCr coatings based on the wear performance evaluation. The off-angle thermally sprayed coatings generally present noticeable degradation in coating feature and characteristic, such as density , microhardness and/or toughness. A critical spray angle was previously suggested for different thermal spray techniques, e.g. HVOF of 45°, wire arc spraying of 60°, plasma spraying of 50° or 45°, primarily based on degree of the degradation benchmarked on that of normal angle. In this study, the feasibility of off-angle HVOF spraying of WC-Ni coatings is clarified directly by wear performance under water lubrication, since reported wear test results seem to be controversial. It is found that, the coating porosity is almost tripled with an upper limit within 3% as reducing the spray angle from 90° to 30°, while the maximum variation in the WC phase retention is about 13.6%, and about 11.7% in both microhardness and elastic modulus, and about 26.4% in indentation fracture toughness, respectively. As compared to a reported dry abrasive wear test showing that specific wear rate of HVOFWC-Co coatings at a spray angle of 30° was nearly doubled to that of 90° within 10−4–10−5 mm3/Nm, our water-lubricated wear test shows a comparably low specific wear rate below 10−7 mm3/Nm with about 30% maximum variation for WC-10Ni coatings off-angle sprayed with respect to that of normal spray angle. A notable reduction in friction coefficient is confirmed for off-angle sprayed coatings at 30° and 45°. The improved tribological behavior ismainly attributed to the higher porosity with well-dispersed micro-pores facilitating a better water lubrication, as well as the mostly retained mechanical properties of off angle coatings due to controlled porosity in a certain range. The off-angle sprayed WC-Ni coatings down to the spray angle of 30° are applicable in tribological applications due to improved fluid lubricating characteristic.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|