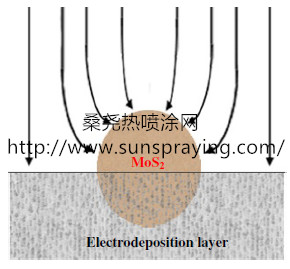

The field of particle inclusion into electrodeposits by the combination of electrophoretic deposition has been comprehensively reviewed. Successful studies of the codeposition of solid lubricants into a nickel matrix, include Ni-Co-MoS2, Ni-MoS2 , Ni-W-MoS2 coatings and Ni-WS2. With MoS2 particle inclusions, Ni-Co composite coatings showed a reduced COF of 0.15–0.23 under loads of 1–4 N in contrast to 0.35–0.53 in the absence of a solid lubricant. Cobalt salts, such as the dichloride and sulphate, however have been categorized as ‘substances of very high concern’. Electroplating of cobalt- based coatings is likely to face stricter regulation in the future. In other composite coatings, a high volumeofMoS2 particles have been incorporated, e.g., 20% wt. MoS2 particles were embedded in a Ni matrix and 40% in Ni-W. These composite coatings had a high surface roughness and showed irregular sponge-like structures with large pores. The resultant, loose coatings could easily be wiped away and the increase in MoS2 content did not result in low friction. Ni-P alloys possess many advantages over other Ni-based coatings including higher hardness and wear resistance. Although Ni-P coatings are amongst the very few candidates to reach 1000 HV which may indicate they can be a potential replacement for hard chrome, there are few reports on the preparation of Ni-P-MoS2 by electrodeposition. The only reported Ni-P-MoS2 coatings were prepared by electroless deposition, with the unstable COF valued from 0.1 to 0.8. However, the high bath temperature (85 °C) and unstable chemicals required by this approach would present a hostile working environment. The present research aims to develop a near frictionless and robust coating at lower bath temperature by electrodeposition. As one of few coating matrices reaching a Vickers hardness of 1000, Ni-P is an ideal candidate for a hard coating.MoS2 particles acting as a lubrication reservoir will be incorporated into a robust Ni-P coating as well as be protected from oxidation. This self-lubricating coating will use less or do not require oil-based lubricants which is expected to attract considerable research and commercial interest. Tribological coatings with low coefficients of friction are in high demand by various industries since they can improve machine efficiency and have an environmental impact. A self-lubricating Ni-P-MoS2 composite coating has been successfully deposited on a mild steel substrate by electrodeposition. The effects of MoS2 on the tribological coatings have been investigated. Compared to a pure Ni-P coating, the Ni-P-MoS2 composite coating exhibited a dramatic reduction in friction coefficient against a bearing steel ball from0.45 to 0.05. Examination and analysis of the worn surfaces and wear debris, the composite coating showed minimum wear and oxidation compared to the severe wear and oxidation observed in the pure Ni-P coating. The evolution of MoS2 particles in sliding wear has been elucidated.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|