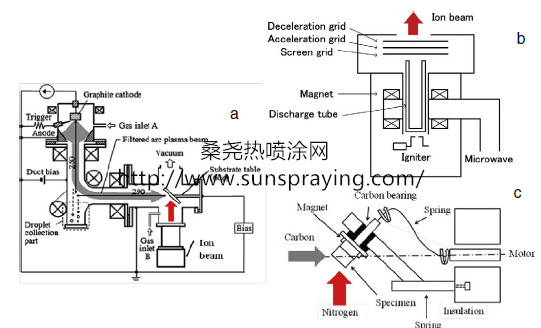

Therefore, it is vital to improve the mechanical properties of a-CNx to ensure sufficient durability. For this purpose, nitrogen was doped into tetrahedral amorphous carbon (ta-C) in this study, and the coatings were named tetrahedral amorphous carbon nitride (ta-CNx). It is known that ta-C is produced by highly ionized plasma. Filtered arc deposition (FAD) is widely used for the deposition of ta-C because it can supply a highly ionized carbon source In this study, the carbon source was a filtered cathode arc and nitrogen was added by accelerated electron cyclotron resonance (ECR) ion beam. The nitrogen gas partial pressures were set at different values by controlling the nitrogen flow rates, in order to fabricate ta-CNx coatings with varying nitrogen contents. For the actual applications in lubrication coatings of mechanical components, the evaluation on the films with oil-lubrication is necessary since most of the mechanical components use oil lubrication. However, only a few studies on tribological properties of CNx coatings under oil lubrication have been reported. Therefore, we investigated the tribological properties of ta-CNx coatings Poly-α-olefin 4 (PAO 4) lubrication in this study. Carbon nitride (CNx) coatings exhibit a wide range of attractive properties that make themsuitable for demanding mechanical and tribological applications. In this study, an ion beamass is ted filtered arc deposition (IBA-FAD) method has been developed for the deposition of tetrahedral amorphous carbon nitride (ta-CNx) coatings. The ta-CNx coatings with various nitrogen contents were deposited by controlling the nitrogen flow to investigate the effects of nitrogen content on their tribological behavior. The composition and structure of the ta-CNx coatings were evaluated using X-ray photoelectron spectroscopy (XPS) and Raman spectroscopy. The tribological properties were examined using a ball-on-disk tribo-tester under oil lubrication condition. The results showed that nitrogen contents of ta-CNx coatings were restricted to the range of 0–11 at.% by nitrogen ion density. The hardness decreased with an increase in the nitrogen content as nitrogen decreased the fraction of sp3 carbon in the coatings. The ta-CNx coatings exhibit low friction under oil lubrication and the maximum value was obtained for samples containing 8 at.% of nitrogen. ta-CNx with 8–11 at.% of nitrogen exhibited markedly low wear rate.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|