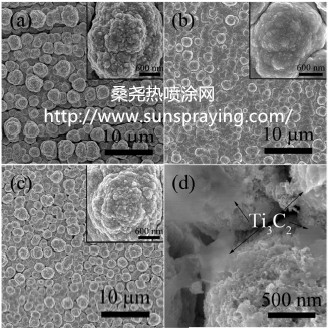

In the search for novel lubricants to combat friction and wear of ever-evolving moving mechanical assemblies, two-dimensional (2D) materials have gained tremendous attention. Taking graphene nanosheets as an example, many works have demonstrated they are effective for friction and wear reduction not only as solid lubricants but also as additives of solvents and nanofillers of composite materials. MXenes, a novel family of 2D materials, are transition metal carbides and/or nitrides which are produced by selective etching of the A group element from MAX phases, where Mrepresents transition metals, A is IIIA or IVA element, and X is carbon and/or nitrogen. Thanks to their unique physical and chemical properties, MXenes have shown great potential in various applications including energy storage, electromagnetic interference shielding, photo-, electro- and chemical catalysis, and so on. Despite these achievements, MXenes' potential as lubricants remain relatively unexplored. Li's group and Liu et al. reported that the incorporation of Ti3C2 additives greatly improved the frictionreducing and anti-wear ability of base oil. Wang et al. showed that the addition of accordion-like Ti3C2 nanoparticles reduced the adhesive wear and plough friction of Ti3C2/ultrahigh molecular weight polyethylene composite. Furthermore, Sinnott et al. predicted by computational study the coefficient of friction (COF) for interlayer sliding of Ti3C2 between 0.24 and 0.27 for normal loads less than 1.2 GPa. All of these findings suggest Ti3C2 nanosheets, the most commonly studied MXenes, are promising lubricants. However, up to now, no reports are available on the synthesis and macro-scale tribological properties of MXenes incorporated metal matrix composites. While MXenes have been strongly studied in the possible applications including energy storage, electromagnetic interference shielding, photo-, electro- and chemical catalysis, its tribological potential as a lubricant remains relatively unexplored. Here, few layer Ti3C2 nanosheets/copper composite coatings are designed and synthesized by a facile electrodeposition technique at room temperature. Their tribological behaviors are studied under dry sliding. Post-test observations including morphology and composition analysis on the wear tracks along with counterpart are conducted to understand their friction and wear mechanisms. The results show that Ti3C2 nanosheets/copper composite coatings exhibit lower of friction and wear rate than their Ti3C2-free counterparts. Our results firstly demonstrate the feasibility of using MXenes as lubricating nanofillers to significantly improve tribological properties of metal matrix composites.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|