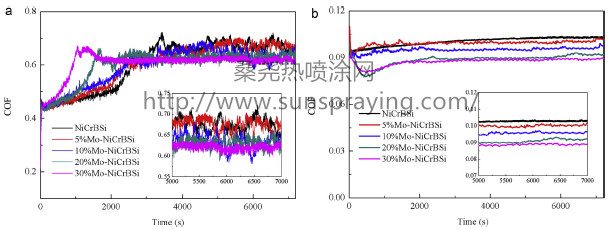

In some cases, high hardness and low friction coefficient are simultaneously needed. Mo and NiCrBSi can be used to formulate a composite material with excellent tribological properties. It is reported that incorporating Mo into NiCrBSi coating also improves the anti-seizure performance. During the friction process, Mo can be oxidized and form a MoO2 film rapidly. MoO2 film has good lubricating properties and thereby prevents the direct adhesion of rubbing surfaces, which reduces significantly friction. On the other hand, under oil-lubricated conditions, Mo can be easily sulfured owing to the high flash temperature and local pressure on the rubbing interface, which thereby leads to the formation of MoS2 boundary film. MoS2 is well known for good lubrication performance and a high anti-corrosion capability as well. Particular in boundary lubrication and in the case of oil starvation, MoS2 tribofilm carries the significant load and hinders the direct rubbing of the friction pair. Niranatlumpong et al. studied the influence of Mo content on the friction and wear properties of Mo- NiCrBSi coating under dry friction condition. Results showed that 25 wt.% Mo-NiCrBSi coating exhibited lower hardness, higher porosity but better wear performance than pure NiCrBSi coating when tested under dry sliding conditions. Yet, excessive Mo reduces the interlayer adhesion and results in coating failure related to interlamellar debonding. Still, the tribological behaviors of Mo-NiCrBSi coatings have been investigated by several research teams, some reports were published about the friction measure under oil-lubricated conditions. However, the dependence of the tribological performance on Mo content has not been demonstrated. NiCrBSi is a material widely used for preparing wear-resistant coatings. In order to study the role of molybdenum (Mo) on tribological performance under dry and oil-lubricated conditions, Mo-NiCrBSi composite coatings were prepared by atmospheric plasma spraying. The contents of Mo in the composite coatings were ranged from 5 to 30 wt.%. X-ray diffraction, optical microscopy and scanning electron microscopy were used to characterize the phase structure and surface morphology of the composite coatings. The tribological performance of the coatings was estimated by reciprocating friction tests. The worn surface was inspected by X-ray photoelectron spectroscopy and energy dispersive spectroscopy to further analyze the wear mechanism. The results showed that the 30 wt.% Mo-NiCrBSi coating exhibited an optimal tribological performance under both the dry and oil-lubricated conditions. The wear resistance of NiCrBSi coating increased when adding 30 wt.% Mo under oil-lubricated condition. It was revealed that MoO2 and MoS2 tribo-films were generated in the friction process under dry condition and oil-lubricated condition, respectively, which accounted for the excellent tribological performance of the composite coatings.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|