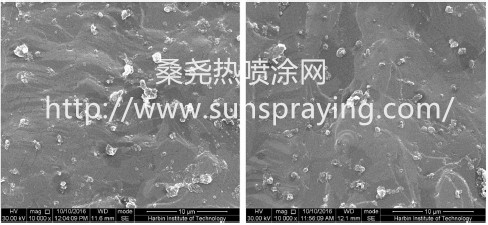

MAO ceramic coatings contained many crater-like micro-pores Of various sizes and a small number of micro-cracks. This creates the possibility of depositing small lubricants into these micro-pores and micro-cracks to form micro-arc oxidation self-lubricating composite coatings. Paraffin has low shear strength and is often used as a solid lubricant. Moreover, the molten liquid paraffin has good liquidity. In this paper, 2024 aluminium alloy was treated with microarc oxidation using a pulsed bipolar current mode at different cathode pulse-widths in the silicate system electrolyte. After the micro-arc oxidation coatings were formed, the micro-pores and micro-cracks on the surface of the MAO ceramic coatings were filled with molten paraffin for preparing micro-arc oxidation selflubricating composite coatings containing paraffin. The microstructure and tribological properties of MAO ceramic coatings were investigated. The adhesion strength between the coatings and substrates was analysed. The tribological properties of micro-arc oxidation self-lubricating composite coatings were analysed. Micro-arc oxidation coatings were prepared on 2024 aluminium alloy using a pulsed bipolar power supply at different cathode pulse-widths. The MAO ceramic coatings contained many crater-like micropores and a small number of micro-cracks. After the MAO coatings were formed, the coated samples were immersed in molten paraffin. These micro-pores and micro-cracks on the surface of MAO ceramic coatings were filled with molten paraffin to prepare micro-arc oxidation self-lubricating composite coatings containing paraffin. The microstructure and properties of the MAO coatings and the wear resistance of micro-arc oxidation self-lubricating composite coatings were analysed by SEM, laser confocal microscope, XRD, a Vickers hardness tester, scratch test and ball-on-disc abrasive tests. The results revealed that the wear rates of the MAO coatings decreased significantly with increased cathode pulse-width. The friction coefficient of MAO self-lubricating composite coatings increased with the increase in cathode pulse-width. The wear rates of MAO self-lubricating composite coatings first decreased and then increased with increased cathode pulse-width. Compared to the MAO coatings, the micro-arc oxidation self-lubricating composite coatings exhibited a lower friction coefficient and lower wear rates.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|