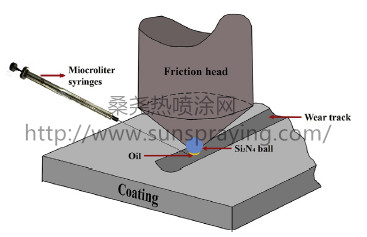

In the past few decades, owing to excellent corrosion resistance, wear resistance at high temperatures and low manufacturing cost, Al2O3-13%TiO2 (AT13) coating have been used widely. And previous studies mainly focused on mechanical properties, microstructure and phase transition from α-Al2O3 to γ-Al2O3 during deposition. With further technological development, research focuses shifted towards the optimization of spraying parameters, the adjustment of powder ratio of Al2O3 and TiO2, and the influence of incorporating alloys or ceramics. Vargas et al. discussed the effect of the proportion of Al2O3 and TiO2 on tribological performances of coatings and experiments, which demonstrated that the wear-resistance of the as-sprayed AT13 coating was superior over that of Al2O3-43%TiO2. Tian et al. deposited AT13 nanostructured ceramic coatings, and found that the hardness, toughness and bonding strength of coatings are both superior over those of Metco 130 coatings, which were primarily related to the net structures of coatings. Bagde et al. demonstrated that with the addition of graphite, the tribological performance of AT13 coatings improved and they ascribed this improvement to the influence of tribofilm. To further extend the service life of coatings, a certain amount of lubricating oil is often added to the working surface of mechanical parts. Under the condition that fluid dynamic pressure film and elastohydro dynamic lubrication film cannot be obtained (i.e. low-speed and heavy-load condition), the tribofilm is formed onto friction interface during friction, which can significantly reduce friction and wear. Although ceramic coatings with higher hardness can effectively extend the boundary lubrication time, the coating will quickly wear out when the lubricating oil is exhausted. Thereby, researchers have improved the tribological properties of ceramic coatings by incorporating alloy elements and developing multiple self-lubricating composite coatings. Deshpande et al. comprehensively considered the influence of Mo element on tribological performances of TiO2 ceramic coatings and revealed that MoS2 grows onto TiO2 substrate in the shape of long crystal flakes during friction. Papken et al. also pointed out that the incorporating of Mo could greatly reduce friction coefficient of coatings and accounted it for the formation of MoS2 in the course of friction. However, research concerning the role of Mo on tribological properties of AT13 coatings under boundary lubrication condition has been seldom reported in the literature. The role of Mo alloy element on the tribological behaviors of AT13/Mo coatings sliding against Si3N4 balls under boundary lubrication condition was investigated. The results revealed that the AT13 and AT13/Mo coatings were mainly composed of γ-Al2O3, α-Al2O3 and TixOy ceramic phases and both coatings underwent a transition from boundary lubrication to dry friction. Furthermore, the addition of Mo could greatly reduce friction. Moreover, the tribological properties of AT13/Mo coating under boundary lubrication condition were superior over those of pure AT13 coatings. According to XPS results, Mo has undergone a chemical reaction to generate a tribofilm covering the friction interface under boundary lubrication condition, and the film containing MoS2 and MoO2 can greatly enhance load-bearing capability and provide good boundary lubrication effect.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|