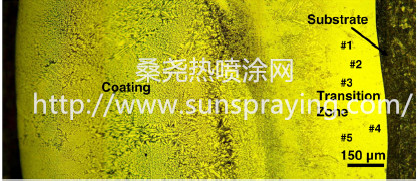

Wear and corrosion are ubiquitous as two of the most common failure modes for many engineering materials, especially for those working at high temperatures and aggressive service conditions such as tribological components in advanced industrial gas turbines and power generation plants. High performance wear resistant materials together with excellent corrosion and high temperature oxidation resistance are required. While wear, corrosion, and oxidation are primarily surface related properties and the replacement by newly designed materials is often less cost-effective, developing a wear and corrosion resistant coating that can resist high temperature would be one of the most straightforward and economical solutions for above problem. Laser cladding is an advanced coating technique that can fabricate dense and uniform coatings with producing relatively small heat affected zone and forming strong metallurgical bonding but small intermixture with the substrates. It is versatile to fabricate various coating materials with high efficiency and controllable thickness on various substrates. The substrate alloy serves as a heat sink during the laser cladding process, and allows for relatively fast solidification rate to give significant grain refinement, which in many cases is helpful to enhance the wear and corrosion performance. The laser cladding process is advantageous over many traditionally used techniques such as cementation and carburizing processes for improving the wear and corrosion resistances. These processes, as usual diffusion coating techniques, were time consuming due to the nature of slow diffusion process. Moreover, the merit of the coatings is strongly substrate dependent and only traditionally employed for specific materials. The thickness of the coating is very limited in many cases (i.e.,smaller or approximately 50 μm), and the protectionwill disappear after the removal of the thin layer by wear in many aggressive service conditions. While versatility in many circumstances is hard to be obtained from a single material, multiphase materials have been designed and demonstrated to successfully combine and balance the properties of their constituting phases. Many ternary transition metal silicides crystallized in the structure of the topologically closed packed (TCP) hP12 MgZn2 type Laves phase, such as W2Ni3Si, Ti2Ni3Si, Mo2Ni3Si and Co3Mo2Si [19–23], exhibited inherent brittleness otherwise could tend towards real application as high performance wear and corrosion resistant materials, owning to their inherent high hardness, yield anomaly, anomalous hardness–temperature dependence, and strong covalent-dominated bonding nature. Cobalt-base solid solution (hereafter referred as Coss) was well recognized for its excellent property combination of ductility, strength, and corrosion resistance. A dual phase alloy with the hard Co3Mo2Si as the wear resistant reinforcing phase and the ductile cobalt-base solid solution as the toughening matrix is expected to be a promising wear and corrosion resistant material with good stability at elevated temperatures. In our previous study , Co3Mo2Si/Coss dual phase alloys were fabricated by laser-melting process, and demonstrated to possess excellent combination of strength and ductility and exhibit excellent wear resistance at elevated temperatures of 400–600 °C. In this paper, a dual phase in-situ composite coating consisting of hard and strong Co3Mo2Si intermetallic phases embedded in the ductile Co-base matrix were fabricated by the laser cladding process on austenite stainless steel. The microstructures of the coatings were characterized by the optical microscopy (MO), X-ray diffraction (XRD), and scanning electron microscopy (SEM) with an energy dispersive X-ray analysis (EDX). The room temperature dry sliding wear property of the Coss/Co3Mo2Si coatings was evaluated and the wear behaviors were discussed.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|