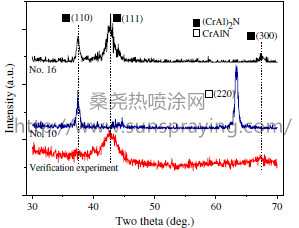

Improvement in the surface properties of tools is very important for engineering applications. Hard coatings prepared by physical vapor deposition (PVD) processes have been used for many years. Chromium nitride (CrN) is usually utilized for hard protective coatings because of its good corrosion and oxidation resistance [3–6]; however, the oxidation resistance for high-temperature applications of conventional CrN coatings is quite limited. The ability to retain the desired properties at elevated temperatures is critical for coatings used in cutting tool and die casting applications. The incorporation of Al to CrN results in higher hardness, as well as thermal and chemical stability. Because of the high solubility of CrN to AlN, Cr–Al–N coatings can be prepared with a wide range of compositions. The theoretical maximum solubility of fcc-AlN in fcc-CrN is approximately 77 at.% .Hard Cr–Al–N coatings possess various physical and mechanical properties, but generally researchers have focused on a single goal for their experiments, thereby neglecting other important properties. Cr–Al–N can be used as a protective coating for plastic injection molds which require not only wear resistance, but also anti-sticking properties. The anti-sticking property is related to the water contact angle (WCA). Coatings possessing a higher WCA and lower polar components of surface energy exhibit higher water-repellency, known as the hydrophobic property. For this reason, it is necessary to implement an efficiency approach for optimizing the multi-objective properties. Multi-objective optimization problems in various applications have been widely discussed but rarely applied to the PVD process. In this study, a hydrophobic and wear-resistant Cr–Al–N coating was developed. The Cr–Al–N coatings were deposited in Ar/N2 plasma using the reactive magnetron sputtering process. For optimizing and balancing the performance of WCA and wear-rate properties, the two signal-to-noise ratios (SNRs) were combined into a performance index by means of the gray relational analysis (GRA), in order to determine the optimal experimental parameters. The Cr–Al–N coatings deposited at the optimization parameters were further annealed at evaluated temperatures to investigate the thermal effect on the hydrophobic property. The objective of this study is to develop a hydrophobic and wear-resistant Cr–Al–N coating .The Cr–Al–N coatings were deposited in Ar/N2 plasma using the reactive magnetron sputtering process. The hydrophobic and wear-resistant properties of the coatings were evaluated by means of the water contact angle (WCA) measurement and ball-on-disk tests, respectively. As for the experimental design, L18 (21×37) orthogonal array experiments were used for statistical purposes to optimize the deposition parameters. Eight process control factors were selected to study their contributions to the hydrophobic and wear-resistant properties of Cr–Al–N coatings. For optimizing and balancing the performance of the hydrophobic and wear-resistant properties, a gray relational analysis is applied to combine the two signal-to-noise ratios of the intrinsic properties in a performance index. The optimal experimental parameters can be determined. The properties of the Cr–Al–N coatings with the optimized parameters show that the WCA of the coatings increases from64.7° to 100.1°,while the wear rate decreases from 3.67×10−5 to 2.38×10−5 mm3 N−1 m−1. The gray relational grade increases from 0.40 to 0.79. This indicates that the gain for the multiple performance index is 39% positive. The Cr–Al–N coatings deposited at the optimized parameters were further annealed at evaluated temperatures to investigate the thermal effect on the Cr–Al–N coatings. The experimental results show that the Cr–Al–N coatings possess hydrophobic properties after annealing below and at 800 °C. With annealing temperatures greater than 900 °C, the coatings become hydrophilic and the WCA is only 45° after annealing at 1100 °C.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|