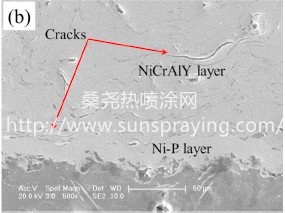

Mg alloys possess many outstanding advantages such as low density, good machinability and exceptional strength-to-weight ratio, which makes them become a preferred choice for weight reduction in the aerospace, automotive and electronic industries. However, the poor corrosion and wear resistance of Mg alloys restrict their applications in these fields. Arose in the 20th century, micro-arc oxidation and electroless plating are widely used to improve the surface properties of Mg alloys. Even so, these single surface treatment methods cannot ensure the long-term use of Mg alloys in severe conditions and the type of materials also has great limitations. Recently, there are some promising works have been done to intensify the performances of Mg alloys. Xu et al. reported the fabrication of ZrC-ZrB2/Ni and Al2O3-TiB2-TiC/Al cermet coatings on MB26 Mg alloy by atmospheric plasma spraying (APS). Bakhsheshi-Rad et al. prepared a triple-layer NiCrAlY/nano-YSZ/PCL coating on MgeCa alloy. The results showed that the as-deposited coatings could make a big difference on the wear and corrosion resistance of substrates. In spite of this, the coatings usually have poor bonding strength with substrates by reason of the serious thermal oxidation on the surface of Mg alloys during APS. So, a proper intermediate layer is essential to fabricate workable coatings on Mg alloys by thermal spraying. Fan et al. had successfully fabricated the thermal barrier coatings (TBCs) on MB26 alloy with NieP or Al interlayer, and found that the interlayer could efficiently improve the thermal shock life and bonding strength of the TBCs. TiB2-TiC-based cermets combine the excellent wear resistance of ceramics with the toughness and ductility of metals. In several works, a variety of metals were added into the Ti-B4C system to synthesize TiB2-TiC-based cermets via self-propagating high-temperature synthesis (SHS). The results indicated that the metallic binder not only significantly enhanced the sintering performance of TiB2-TiC ceramics, but also led to a certain degree of grain refinement because of the decreasing adiabatic temperature in the reaction systems. However,too much metal addition will in turn weaken the properties of cermet materials. The diluents are optimal choices to maintain the content of resultant ceramics together with grain refinement. NaCl has been used as the SHS diluent for the remarkable superiorities of economy, chemical neutrality and easy to remove TiB2-TiC-Co cermet coatings were fabricated on AZ91D Mg alloy substrate by atmospheric plasma spraying (APS) using the powders produced by self-propagating high-temperature synthesis (SHS) from Co-Ti-B4C system. In order to improve the bonding stability between cermet coating and substrate, the interlayer of Ni-P/NiCrAlY was prepared by the combination of electroless and APS methods. Microstructure and phase composition of the SHS products and coatings were investigated. Correlation between microstructure and wear properties of the cermet coatings was discussed. The results showed that the interlayer prevented Mg alloy substrate from oxidation or ablation, and bonded tightly to both the substrate and cermet coating. The tensile failure of triple-layer coatings was mainly located at the interface between the NiCrAlY layer and NieP layer, with the bonding strength of 21.4±3.2 MPa. The two cermet coatings with different grain sizes of TiB2-TiC provided good wear resistance for substrates owing to their high hardness of about 1059 and 1018 HV, respectively. Moreover, the cermet coating composed of finer ceramic particles exhibited a more compact and uniform structure, which led to a significant reduction in wear rate and friction coefficient. The wear mechanisms of cermet coatings against alumina-ball counterpart were a mix of exfoliation of hard phases and abrasive wear by micro-cutting.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|