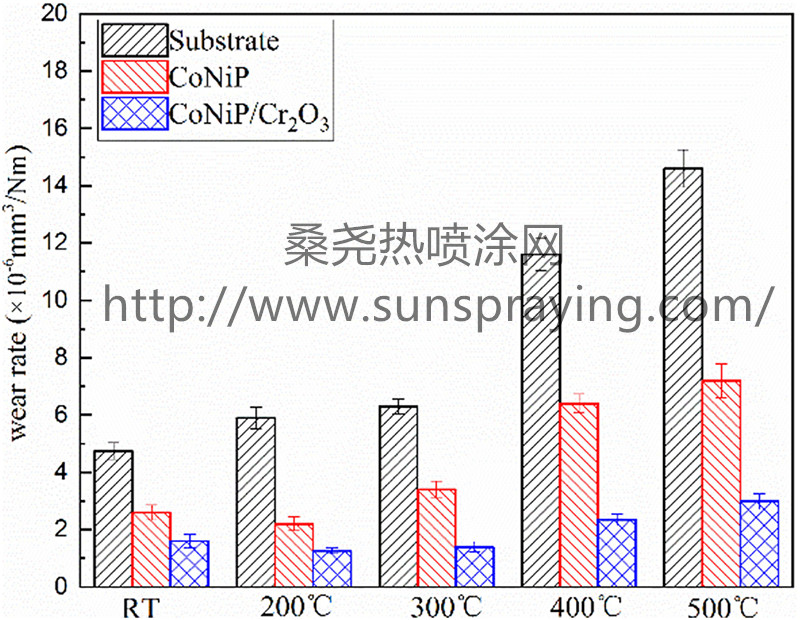

Electrodeposited hard chrome coatings have been widely used in industrial to improve the service life of mechanical parts due to its high wear resistance and corrosion resistance. However, the traditional process of electroplating hard chrome produced Cr6+, and was harmful to the environment. In recent years, Co-based coatings, especially CoP have attracted much attentions because of their high deposition efficiency, excellent mechanical properties, and the plating process is environmentally friendly as compared to that of the chrome. These coatings are considered to be the most promising alternative materials for plating chrome coatings. Many researchers applied electrodeposited Co-based coating process for the modification and repair of aircraft and naval mechanical parts. CoNiP coatings are commonly used as electrolytic materials of water electrocatalytic, magnetic materials, microwave absorbing materials. Maet al. reported that the CoNiP coatings annealed at 400 °C have low friction and excellent wear resistance at room temperature, and it can be a potential substitute for the electroplated hard chrome. CoNiP coatings have the potentiality to be used at elevated temperature conditions, for example, on some parts of aero engine and fast-fire weapon for better high temperature wear resistance performance. However, few studies have been done on the tribological and wear properties of CoNiP at high temperatures. Therefore, it is essential and urgent to study the friction and wear behavior of CoNiP coatings at high temperatures. In general, the incorporation of ceramic particles can further improve the performance of the coating, and this method can be applied onto the Co-based composite coatings to obtain excellent wear resistance properties. Cr2O3 particles have been confirmed as a beneficial ceramic particles for improving the wear and corrosion resistance of electrodeposited coatings, and in this paper, Cr2O3 particles were incorporated in the electrodeposited CoNiP coatings, to further improve the properties. The aim of this paper is to investigate the wear properties at different temperatures of the CoNiP/Cr2O3 composite coatings after heat treatment, to study the effects of Cr2O3 particles contents on the microstructures and wear resistance of the electrodeposited CoNiP and CoNiP/Cr2O3 composite coatings. In this paper, CoNiP and CoNiP/Cr2O3 composite coatings were successfully electrodeposited onto Cr-Ni-Mo-V steels substrate by using direct current (DC). The effects of Cr2O3 particle contents and heat treatment on the microstructures, coating compositions, microhardness and wear resistance properties of the coatings were investigated by scanning electron microscope (SEM), energy dispersive spectrometer (EDS), X-ray diffraction (XRD), Vickers hardness tester and ball-on-disk tribometer. The results showed that the coatings transformed from amorphous to crystalline structures by heat treatment at 350 °C, and their microhardness significantly increased. The contents of Cr2O3 particles in the coatings reached a stable value for the coatings deposited in the plating bath with concentration of Cr2O3 higher than 15 g/L, meanwhile the coating deposited in the plating bath of 15 g/L Cr2O3 (CoNiP-15 g/L Cr2O3) possessed the highest microhardness. Wear test results at room temperature, 200, 300, 400 and 500 °C showed that the wear resistance of the coatings was improved by the addition of Cr2O3 particles, and the CoNiP-15 g/L Cr2O3 coating had the lowest coefficient of friction and wear loss among all the samples.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|