The bond structure in transition metal nitrides consists of a mixture of covalent, metallic and ionic

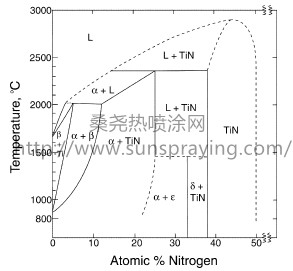

components, and is responsible for high hardness, excellent wear resistance, chemical inertness, good electrical conductivity and superconducting properties. The interest in thin films of metal nitrides is growing rapidly for such diverse applications as wear resistant coatings on cutting tools, selective transmission coatings on architectural glass, and as diffusion barriers in integrated circuits. Of the transition metal nitrides, processing techniques, properties and applications of titanium nitride (TiN) have been investigated extensively. Titanium nitride crystallizes in the B1 NaCl structure and exists as a solid solution containing nitrogen in the range 37.5_/50 at.%1. It is expected that advanced coatings such as (Ti,Al)N and their quaternary and multilayer coatings provide better performance over simple nitrides. Incorporation of aluminum in TiN film improves the oxidation behavior and the thermal stability of the coating. It is well established that (Ti,Al)N coating enhances wear and oxidation resistance of tools, while overcoming the shortcomings of TiN and TiCN coatings. In this paper, we review deposition of (Ti,Al)N coatings and compare the properties and performance of different titanium based coatings. In addition, the recent

works on titanium based multicomponent and multilayer coatings are also discussed. We review the status of (Ti,Al)N based coatings obtained by various physical vapor deposition (PVD) techniques and compare their properties. PVD techniques based on sputtering and cathodic arc methods are widely used to deposit wear resistant (Ti,Al)N coatings. These techniques were further modified to improve the metal ionization rate and to eliminate macrodroplets from plasma streams. We summarize manufacture of target/cathode, substrate materials for deposition of coatings, deposition parameters, and the effect of deposition parameters on the physical and mechanical properties of (Ti,Al)N coatings. It is shown that (Ti,Al)N coatings by PVD enhance the wear, thermal, and oxidation resistance of a wide variety of tool materials. We discuss the wear resistant properties of (Ti,Al)N for various machining applications as compared with coatings such as TiN, Ti(C,N) and (Ti,Zr)N. High hardness (_/28_/32 GPa), relatively low residual stress (_/5 GPa), superior oxidation resistance, high hot hardness, and low thermal conductivity make (Ti,Al)N coatings most desirable in dry machining and machining of abrasive alloys at high speeds. Multicomponent coatings based on different metallic and nonmetallic elements combine the benefit of individual components leading to a further refinement of coating properties. Alloying additions such as Cr and Y drastically improve the oxidation resistance, Zr and V improve the wear resistance, whereas, Si increases the hardness and resistance to chemical reactivity of the film. Addition of boron improves the abrasive wear behavior of Ti_/Al based coatings due to the formation of TiB2 and BN phases depending on the deposition conditions. Hafnium based nitrides and carbides have potential for resistance to flank and crater wear. The presence of a large number of interfaces between individual layers of a multilayered structure results in a drastic increase in hardness and strength. (Ti,Al)N multilayer super lattice coatings with lattice periodicity of 5_/10 nm allow creation of coatings with different properties than PVD deposited single layered thick coatings with columnar grain structure. A range of (Ti,Al)N based multilayers containing layers of (Ti,Al)CN, (Ti,Nb)N, TiN, AlN/TiN, CrN, Mo and WC are also reviewed. It is now possible to design new wear resistant or functional coatings based on a multilayer or a multicomponent system to meet the demanding applications of advanced materials.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|