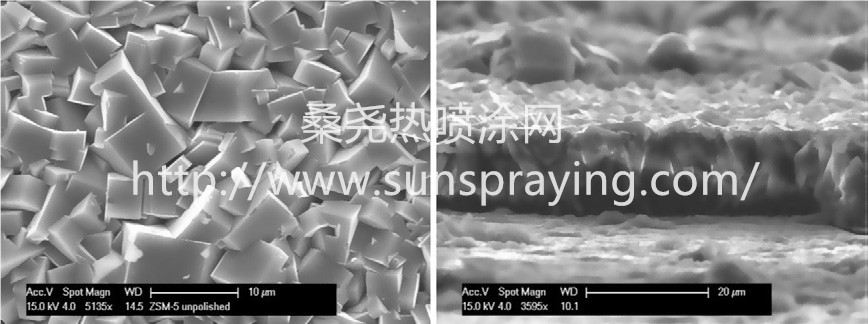

Hard chrome (Cr) coatings are known for their excellent abrasion resistance, low friction coefficient, and their capability to produce thick layers for rebuilding worn parts back to specification. Cadmium (Cd) coatings are critical to aircraft fasteners as a sacrificial wear layer and to provide mild corrosion protection. Both types of coatings remain the industrial standards in wear and corrosion protection even though they are electroplated using precursors that are known for causing cancer and other serious diseases. In addition, the plating baths used for deposition contain hazardous chemicals whose disposal (estimated 675,000 metric tons/year of waste) is a significant environmental problem. Alternatives to chromium and cadmium coatings have long been desired, but new technologies have suffered in either cost, performance, or deposition simplicity. Furthermore, the mindset behind many prospective alternatives remains fixated on mimicking the high hardness and modulus of hard chrome whereas current research suggests that a high hardness with a relatively low modulus may be more beneficial to wear resistance. The low modulus aids in deformation absorption and recovery while the high hardness reduces any permanent deformation done to the coating. Synthetic zeolite powders have been used as catalysts and separation media by exploiting their uniform porosity. Being virtually non-toxic, zeolites have found potential in medical applications such as in magnetic resonance imaging contrast agents and biocompatible coatings for implants where they produce no hazards to human health. Additionally, zeolites are generally accepted as eco-friendly alternatives in catalysis and in many other applications. Zeolites in thin film or coating form have been shown to have many applications including membranes, sensors, and insulators in computer chips. The specific high-silica-zeolite ZSM-5 coating studied in this paper has shown exceptional corrosion resistance . Exhibiting a porous framework, ZSM-5 is expected to have exceptional coating flexibility which serves as a deterrent to coating cracking, an effect often seen on hard chrome as a result of substrate bending and torsion. The coating process has been demonstrated to be able to uniformly coat surfaces of complex shape and in confined spaces. The purpose of this paper is to examine the viability of ZSM-5 coatings in wear resistant applications by characterizing and comparing their tribological properties to commercially electroplated chromium and cadmium coatings. In searching for environmentally friendly alternatives to the widely used hard chrome and cadmium coatings, conventional wisdom has been focusing on materials with a high hardness that is usually provided by dense metals or ceramics, and inevitably accompanied by a high elastic modulus. A preferred wear resistant coating should have a high hardness but a relatively low modulus because a high modulus limits the coating’s flexibility and overall wear performance. Here we show for the first time that zeolite materials, with their unique crystalline porous framework, possess this demanding balance. Zeolites’ crystallinity offers an exceptional hardness while their porosity provides a relatively low elastic modulus. Zeolite coatings are demonstrated to outperform hard chrome and cadmium coatings in wear and corrosion resistance.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|