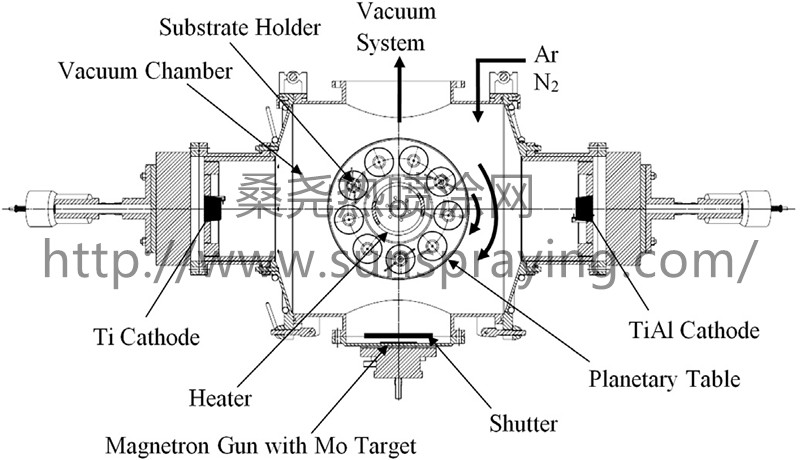

TiAlN based thin films already traditionally belong to the group of wear resistant coatings which among others, single- or multicomponent transition metal nitrides, are used when an improvement of performance and life time of cutting tools is expected. Depending on elemental and phase composition, their hardness can range from 25 to 30 GPa. Due to Al content in TiAlN coatings their oxidation resistance is higher than that of a traditional TiN layer. This is the reason why they are widely used as a protective layer deposited on tools for high speed machining. The presence of Al in TiAlN coatings overcomes the oxidation problems due to the presence of a superficial layer of Al2O3 formed at high temperature.This layer restricts oxygen diffusion and oxidative wear. On the other hand, dry friction coefficient versus steel, registered for that type of coatings is high, reaching 0.9e1.0 at room temperature up to 1.5 at 400℃. Due to high cutting forces it contributes to undesirable increase of tool temperature and promotes wear processes. Reduction of friction forces is possible by appropriate modification of chemical composition of these coatings by introduction of components which form oxides which in turn are able to play a role of solid lubricants. Titanium, vanadium, tungsten and molybdenum are known to form series of oxides that belong to the group of so called Magnelli phases, were specific order of oxygen vacancies leads to formation of easy shear planes. This in turn results in low friction properties of these oxygen deficient compounds. Also the highest oxides of vanadium (V2O5) and molybdenum (MoO3), due to their lamellar structure, show interesting lubricating properties, especially at elevated temperature. The effect of vanadium or molybdenum doping on tribological behavior of TiAlN based coatings have already been studied by other groups. TiAlN based coatings have been deposited by reactive vacuum arc evaporation combined with codeposition of molybdenum from planar magnetron source. Obtained quasi-multilayer TiAlN/(TiAl)1_x- MoxN structure was affected by the specific deposition system geometry. An average molybdenum content was up to 8 at.%. The molybdenum addition resulted in a significant improvement of tribological properties manifesting itself in lowering of friction coefficient vs steel from 0.8 down to 0.5 and wear rate below 1015 m3/Nm. Other mechanical properties like hardness and adhesion remained unaffected or slightly improved. Observed change of tribological response for studied coatings was interpreted as being caused by beneficial contribution of lubricating molybdenum oxides generated in the tribo-contact during friction process. Molybdenum addition also affected corrosion resistance. It resulted in an improved resistance to pitting corrosion accompanied by increase of corrosion potential for coatings tested by the potentiodynamic method in 0.5 M NaCl solution.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|