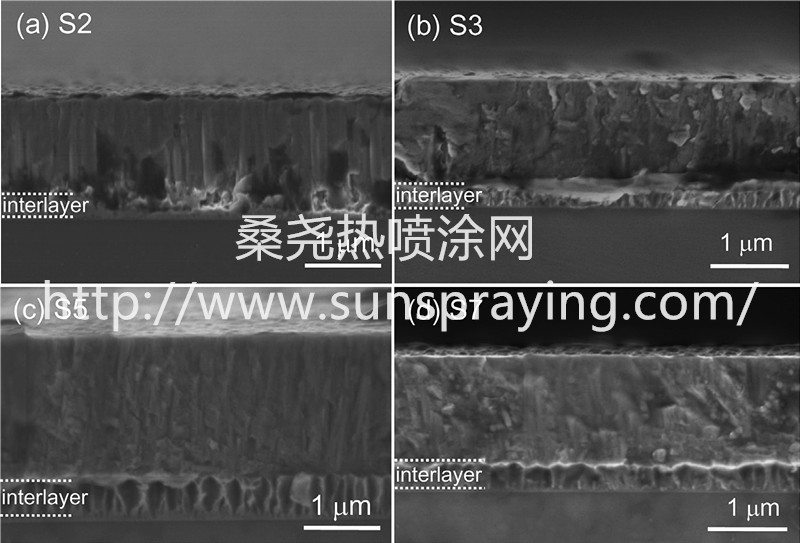

Transition metal borides usually exhibit some attractive properties including high hardness, good wear-resistance, chemical inertness, and electrical conductivity, giving rise of great application potential . More studies have been performed on transition metal boride coatings, such as titanium boride (TiB2), chromium boride (CrB2), niobium boride (NbB2), and zirconium boride (ZrB2). It has been evidenced that superhardness (~60 GPa) can be achieved in TiB2 coatings which consist of TiB2 subcolumns separated by an ultrathin B-rich tissue phase. The 2D nanocomposite structure was also observed in CrB2 coatings by Audronis et al., and the CrB2 coatings show high hardness (~38 GPa) as well as good corrosion resistance. Recently, super-hardness (42 ± 4 GPa) has been obtained in weakly textured substoichiometric NbB2-x coatings. Vanadium boride (VB2) is another kind of transition metals boride in hexagonal C32 structure with lattice parameters 0.2997 nm and 0.3056 nm. For strong covalent bonds in the B network, VB2 has a high melting point (2747 ℃, and a high hardness (~21 GPa) . Furthermore, VB2 could be expected to afford low friction on dry sliding surfaces. In addition to the formation of an ultralow-friction H3BO3 on surfaces, self-lubrication can be achieved in VB2 coatings by the formation of lubricious vanadium oxides at elevated temperature. Erdemir et al. observed the formation of some liquid-like islands, and further deduced that the islands composed primarily of vanadium oxidesduring annealing of the VB2 samples. Some beneficial effects, such as lower friction coefficients and/or specific wear rates, have been observed in coatings containing sufficient amount of vanadium. Previously several studies have investigated the phase composition and microstructure of the VB2 coatings that were prepared by thermodiffusion process or radio frequency magnetron sputtering. However, there has been very limited information for the VB2 coatings deposited by pulsed DC magnetron sputtering. Vanadium boride (VB2) coatings have been less concerned, although they have advantages of superhardness as well as self-lubrication. In this study, VB2 coatings were deposited by pulsed DC magnetron sputtering, and the effect of deposition parameters on the microstructure, mechanical and tribological properties of coatings were investigated by X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), nano- and micro-indentation, and ball-on-disk tribometer. Under the growth condition with high adatom mobility, the coatings exhibited complete (001) orientation and dense texture. A nanocomposite structure that nanocolumns were separated by a secondary phase was especially observed in the coating deposited at 773 K. Both hardness and intrinsic stress of the coatings were improved substantially by increasing the substrate bias or the pulse frequency. The coating deposited at 30 V and 250 kHz, had the hardness of ~43.6 GPa and the compressive stress of ~2.0 GPa. Under the load of 2 N, the friction coefficients were ~0.7 against Al2O3 counterpart, and the wear rates were in the range. Under the load of 5 N, the coatings with low intrinsic stress showed better wear resistance, with the wear rate of 10_16 m3/N m.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|