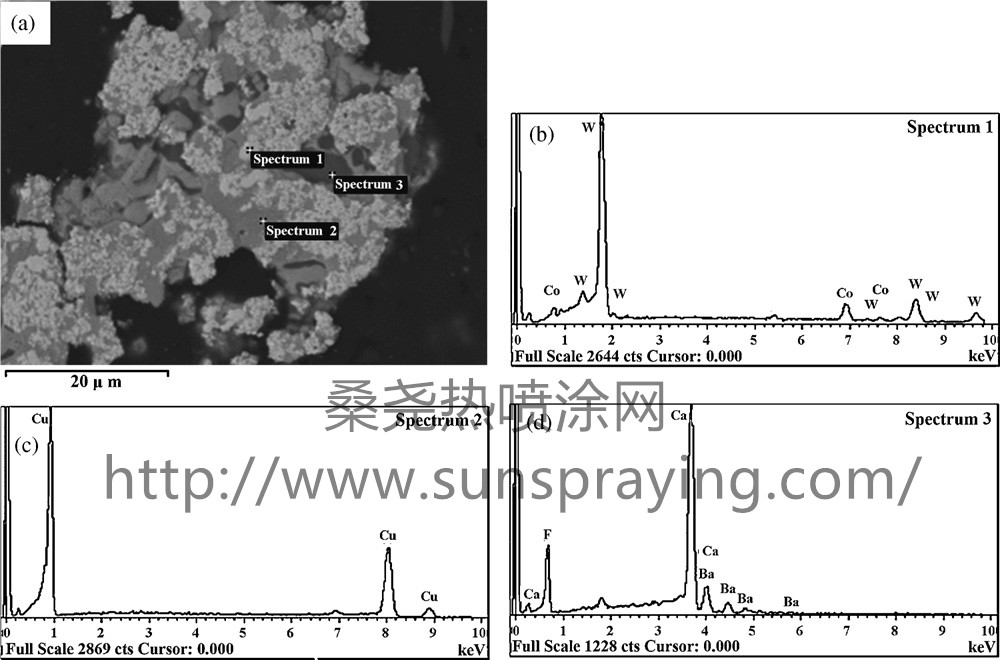

Thermal spray WC–Co coatings are widely used in wear situations because they combine several advantages such as resistance to abrasion, erosion, high temperature and corrosive atmospheres. However, one noticeable problem is that the coatings do not have low friction coefficients and provide no protection for the opposing surface. Therefore, considerable efforts have been made to improve the tribological performance of WC–Co coatings. As opposed to conventional liquid lubrication methods, solid lubrication provides an advantageous alternative for controlling friction and wear in the absence of an external supply of lubricants, and it has been widely used in many modern tribological applications. Fluorides of the alkaline earth metals are chemically inert in strong oxidizing or reducing environments. They are relatively soft and non-abrasive and some of them, such as CaF2, have planes of perfect crystal cleavage in their crystal structure suggesting lowshear strength which may be a reason why these materials act as lubricants. BaF2/CaF2 eutectic is one of the most widely used solid lubricants. To meet the requirements of extreme and demanding tribological applications, advanced lubrication concepts and various complex coating structures have been developed. Ceramics containing solid lubricants have attracted much attention as self-lubricating materials. In earlier studies , some of the ceramic composites, such as Al2O3/CaF2 and SiC/CaF2, have been developed, and the mechanical properties, tribological and microstructural studies have also been extensively carried out on them. Tribological properties of plasma sprayed coatings of ZrO2–CaF2 coatings with and without silver additions were investigated in sliding against superalloys. Self-lubricating composites doped with solid lubricants of BaF2/CaF2 eutectic and Ag in a metal-bonded chromium carbide (Cr3C2) matrix have been developed by plasma spraying and powder metallurgy methods. As a means to further improve the wear resistance of WC–Co coatings, a method of solid lubrication is investigated. For this study, composite coatings consisting of a hard WC–Co matrix co-deposited with Cu and BaF2/CaF2 eutectic are investigated. WC–Co matrix offers excellent mechanical strength. Cu and BaF2/CaF2 eutectic act as solid lubricants. Cu in the coating is expected to keep thermodynamic equilibrium with mild steel substrates and inhibit the decomposition of WC in APS process. The paper gives details of the deposition methods and includes a brief description of the microstructures of the coatings. Furthermore, the sliding wear property of the resulting composite coatings is evaluated by a ball-on-disc tester. The worn surfaces are also analyzed. A promising WC–Co–Cu–BaF2/CaF2 self-lubricating wear resistant coating was deposited via atmospheric plasma spraying (APS) process by using homemade feedstock powders composed of WC–Co, Cu and BaF2/CaF2 eutectic. The as-prepared cermet coatings had better frictional behavior comparing with the WC–Co coating. Moreover, the often-occurred decarburization of WC in APS process was noticeably improved due to the binding of copper and BaF2/CaF2 phase, which not only offered effective solid lubrication, but also acted as bind phases tomendthe microstructure and protectedWCfrom decomposition. The optimized specimen contained 10 wt.% Cu and 10 wt.% BaF2/CaF2 in a WC–Co matrix, which had excellent frictional and wear performance. The wear mechanism of the self-lubricating wear resistant coating was discussed with the microstructures, compositions and mechanical properties of the composite materials in detail.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|