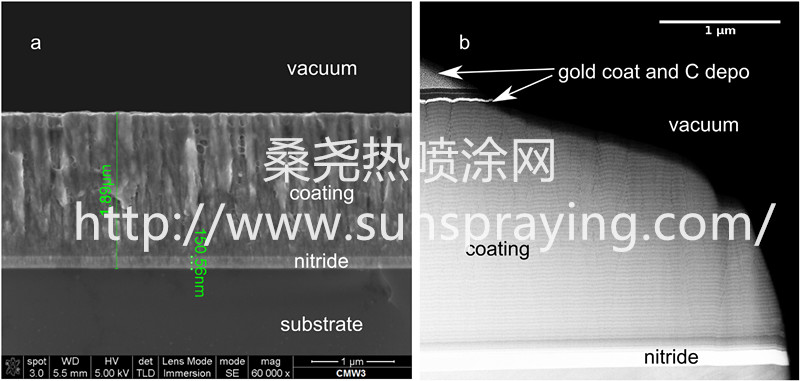

In many industries, wear-resistant coatings are important to increase efficiency, lifetime and performance of moving contact parts. Diamond-like carbon (DLC) coatings, deposited by magnetron sputtering or CVD, display impressively low coefficients of friction and wear rates. These are amorphous coatings similar to the continuous random network of amorphous silicon or germanium, in which sp3 bonding dominates, hence they are referred to as diamond-like. In the case of applications such as automotive engines, increasing the running temperature would also increase the efficiency, thereby reducing energy consumption and carbon footprint. Diamond-like carbon, however, does not perform well as the temperature increases. At ~400 °C a DLC coating begins to graphitise, then oxidise, losing its excellent wear properties as it does so . Other high temperature wear-resistant coating solutions in current development include transition metal dichalcogenides e.g. MoS2, and ternary metal oxides, but these do not keep their good wear properties across a wide temperature range . Films deposited by the high-power impulse magnetron sputtering (HIPIMS) process have been found to exhibit similarly outstanding room temperature wear behaviour to DLCs, and retain this up to higher temperatures. Due to the high energy supplied by incoming ions, coatings grown with the HIPIMS technique experience a great deal of structural rearrangement at the growth surface. The structure of this MoeW doped C coating is similar to other metal‑carbon co-deposited coatings e.g. whilst showing important microstructural differences in the metal incorporation, and shows improved wear resistance under dry sliding conditions . Composite coatings containing solid lubricant phases are part of the current state of the art e.g. , producing good wear properties and a wear surface with inhomogeneity on the micron scale; HIPIMS-produced coatings of the kind investigated here represent a finer (nanoscale), more intimately mixed composite coating that can give an even lower coefficient of friction. These MoeW coatings have been previously investigated by scanning electron microscopy, Raman spectroscopy and low-magnification transmission electron microscopy (TEM), but not with high spatial resolution electron microscopy. In this study, we explore the fine nanostructure of these Mo-W-C films, and find a complex structure of loosely-ordered rosette-like graphitic clusters 3–8 nm in diameter, which were seen “unrolled” into graphitic solid lubricant in the wear experiments published in . Similar onion-like graphitic clusters were previously seen in CreC films co-deposited by steered cathodic arc/ unbalanced magnetron sputtering, with a substrate bias voltage of only -95 V , but are now seen with different metals using HIPIMS and much higher substrate bias. As that CreC coating was made with increased substrate bias voltage up to -350 V, it transitioned to a structure of wider layers (~20 nm) of alternating onion-like C clusters and crystalline chromium carbide . This HIPIMS W-Mo-C system, in contrast, displays two regimes of layering simultaneously: layers of clusters, with a secondary modulation in the density of the layers. The second modulation, and the rosette-like graphitic nature of the metalcontaining clusters at this higher substrate bias of -500 V, are what set this coating apart from previous metal-doped carbon wear-resistant coatings, made through HIPIMS and otherwise. In summary, the goal of this study was to take this Mo/W doped carbon coating that performed well in hot wear tests and determine the micro- and nanostructure that allows this property. It transpires that the structure contains features different from previous similar coatings, therefore this study presents details of a new coating microstructure. Thin films of C/Mo/W deposited using combined UBM/HIPIMS sputtering show 2–8 nm clusters of material richer in Mo and W than the matrix (found by EDS microanalysis), with structures that resemble graphitic onions with the metal atoms arranged regularly within them. EELS microanalysis showed the clusters to be rich in W and Mo. As the time averaged power used in the pulsed HIPIMS magnetron was increased, the clusters became more defined, larger, and arranged into layers with amorphous matrix between them. Films deposited with average HIPIMS powers of 4 kW and 6 kW also showed a periodic modulation of the cluster density within the finer layers giving secondary, wider stripes in TEM. By analysing the ratio between the finer and coarser layers, it was found that this meta-layering is related to the substrate rotation in the deposition chamber but in a non-straightforward way. Reasons for this are proposed. The detailed structure of the clusters remains unknown and is the subject of further work. Fluctuation electron microscopy results indicated the presence of crystal planes with the graphite interlayer spacing, crystal planes in hexagonal WC perpendicular to the basal plane, and some plane spacings found in Mo2C. Other peaks in the FEM results suggested symmetry-related starting points for future determination of the structure of the clusters.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|