Functional coatings with photocatalytic properties offer the most promising means of advanced water pollution control. The principle underlying this application resides in the photo-triggering of

redox reactions that can degrade the pollutants in contact with the surface. Titanium dioxide (TiO2), a wide band-gap semiconductor, is the material chosen for most photocatalytic applications, due to its chemical stability, low cost, and convenience of use. Coating techniques which are able to produce surfaces based on this material, such as sol–gel (SG), magnetron sputtering (MS), pulsed laser deposition (PLD), physical vapor deposition (PVD) or chemical vapor deposition (CVD) have attracted a great deal of interest from both the scientific community and the industry stakeholders. Two drawbacks ensue related to TiO2: on the one hand, the more frequentlyemployed coating technologies for this type of material are either energy- intensive and expensive (CVD, PVD, PLD, MS), or poorly upscalable to pilot or industrial applications (SG). On the other hand, the semiconducting titanium dioxide (irrespective of its polymorphs) can be activated only by UV and deep-blue regions of the electromagnetic spectrum (λ < 390 nm), which account for less than 5% of the total emitted solar radiation [3]. Nowadays, there is a great deal of effort focused on developing cost-efficient methods to obtain TiO2- based photocatalysts, which could efficiently harvest the visible portion of the electromagnetic spectrum. Among other techniques, doping TiO2 with nitrogen has been known to reduce the optical bandgap of this material within the visible domain and to significantly enhance the photocatalytic yield through the prevention of charge carriers recombination. Several direct methods have been employed to date for N-doped titanium dioxide (N-TiO2) coatings achievement, such as sputtering, plasma/ion implantation and sol-gel, in conjunction with nitrogen-containing precursors (urea, ammonia, amines, nitrogen oxides, hydrazine and so forth) that are decomposed during deposition. Indirect methods make use of controlled metallic titanium oxidation in the presence of precursors or, more frequently, oxidation of previously CVD-deposited titanium compounds such as titanium nitride (TiN) or oxynitride (TiON). The drawbacks of these methods are represented by their high cost, use of potentially hazardous precursors, multiple preparation stages, and low upscaling potential.

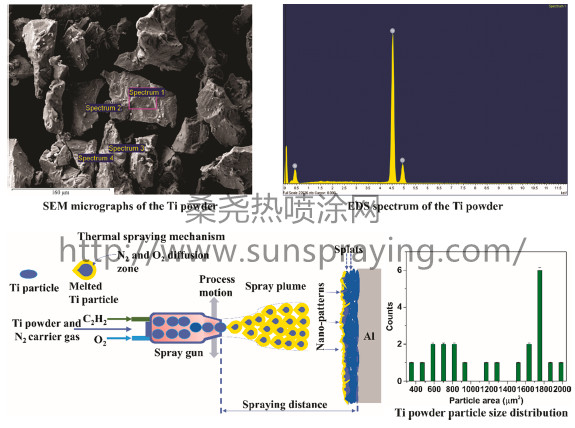

Thermal spraying represents a more versatile, cost-efficient and environmental-friendly technology, with well-known upscalable character. In this method, the feedstock material (powders, liquid precursors, dispersions) is injected in an enthalpic source (flame, plasma) by means of a carrier gas, where the particles are melted (the liquid precursor decomposed, respectively), after which they are accelerated and impacted on the substrate, where they solidify. Plasma spraying (and to a lesser amount flame spraying) has been successfully used so far to deposit 100–500 μm-thick TiO2 coatings, starting from TiO2 powder or from a liquid precursor such as titanium (IV) isopropoxide (TTIP), on various conventional (metal, ceramic) or specialized substrates. Due to the versatility of thermal spraying process, doping of TiO2 or other semiconducting species with transitional metal ions, metal oxides, or hydroxyapatite can be easily achieved in a onestep approach. Due to their good chemical stability, high compactness, good bonding to the substrate, high wear resistance (generally superior to sol-gel films), and nanopatterned morphostructural features (which lead to high specific surface areas, in contrast to most of the thin films obtained by CVD), surfaces obtained by thermal spraying have all the pre-requisites of efficient photocatalytic materials . Up to date, few studies are dealing with the achievement of NTiO2 coatings by flame spraying, among which the most typical use various liquid feedstocks comprised in TTIP mixed with nitrogen-containing precursors. Plasma spraying has been used so far as means of obtaining doped TiO2 coatings in an approach starting from nanometric TiO2 anatase or anatase and rutile-containing powders in conjunction with nitrogen/nitrogen: argon mixtures as carrier gas. Advanced oxidation processes catalyzed by functional surfaces represent one of the most versatile methods for removing potentially toxic and persistent organic compounds from aqueous environments. This study is focused on obtaining two types of coatings with complex surface chemistry, involving titanium dioxide, nitrogen-doped titanium dioxide, titanium suboxides, and titanium nitride through a one-step thermal spraying method, starting from titanium feedstock powder. The differences in morphological and structural characteristics of coatings arise from the two different standoff distances between thermal spray nozzle and aluminum substrate (150mm and 200 mm). The surface energies of the coatings range from 31 to 34 mN/m, which increase with up to 20% upon irradiation with UV light. The optical band gap values of the coatings are 2.01 eV and 1.55 eV respectively, indicating the possibility to harvest electromagnetic radiation from the visible domain in relation to photocatalysis applications. The photocatalytic activity of the surfaces has been tested against methylorange under UV (254 nm and 365 nm) and visible light irradiation. The photodegradation of methyl orange followed a pseudofirst order mechanism, with rate constants in the 0.0039–0.0871 min−1 interval. High photodegradation (91–99%) and dye mineralization (85–97%) efficiencies were registered for both types of coatings.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|