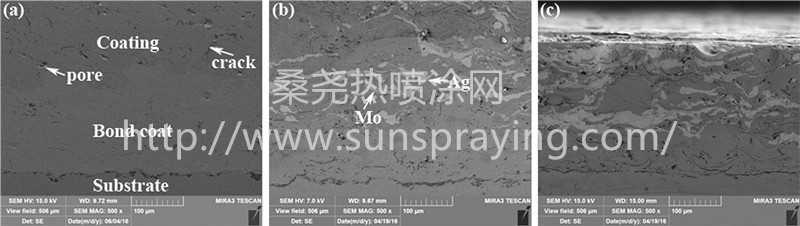

MCrAlY (M = Co or/and Ni) coatings prepared by thermal spraying technique have been diffusely used in the industries of nuclear power, aerospace and automotive owing to the excellent high-temperature corrosion and oxidation resistance and it could withstand the high thermal and mechanical loads due to possessing excellent high-temperature self-lubricating properties. Graphite and molybdenum disulfide usually acted as solid lubricants could improve the tribological properties of the composites. But this kind of solid lubricants would be oxidized or decomposed above 500 ℃, and therefore lose their lubricating effects. Silver could decrease the wear rate and friction coefficient of the composites and provide the excellent lubricating effect below 400 ℃ due to a low shear strength and large diffusion coefficient on the worn surfaces during the sliding process. An et al. prepared the NiMoAl–Cr3C2–Ag composite coatings by high-velocity oxy-fuel (HVOF) and demonstrated that the incorporation of silver could efficiently improve the tribological properties of the composite coatings. Our previous studies showed that increasing the silver contents could decrease the wear rate and friction coefficient of the composites by power metallurgical sintered. In recent years, due to excellent lubrication performance in wide temperature range, Ag–Mo dual-lubricant has been investigated by several researchers. Chen et al. fabricated the NiCrAlY–Ag–Mo composite coatings by atmospheric plasma spraying (APS), which possesses excellent tribological properties at the wide range of temperature, but there are few studies on the influence of the silver contents on the mechanical properties and tribological properties of the coatings. The NiCrAlY–Mo–Ag composite coatings were prepared by atmospheric plasma spraying. The tribological properties of the composite coatings were investigated from 25 to 900 ℃ in details. The tribo-layer formed on the worn

surface of the composite coatings and influenced the tribological properties at different temperatures. The addition of silver could effectively decrease the friction coefficient and wear rate of the coatings at the wide range of temperature. The rubbing process could form the nickel molybdate and promote the formation of silver molybdate within the worn surfaces at high temperature. The synergistic lubricating effects of nickel molybdate and silver molybdate are attributed to the improvement of the tribological properties of coatings at high temperature. The composite coatings are composed of Ni3Al, NiAl, Ni and Y2O3 phases. The Y2O3 phase is the oxide dispersion strengthening phase which can improve the strength of the composite coatings. The addition of silver can effectively improve the tribological properties of composite coatings at a wide range of temperature. The rubbing process could form the nickel molybdate and promote the formation of the silver molybdate on the worn surface at high temperature. The silver molybdate and nickel molybdate tribochemical reaction films could effectively improve the tribological properties of composite coatings at high temperature.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|