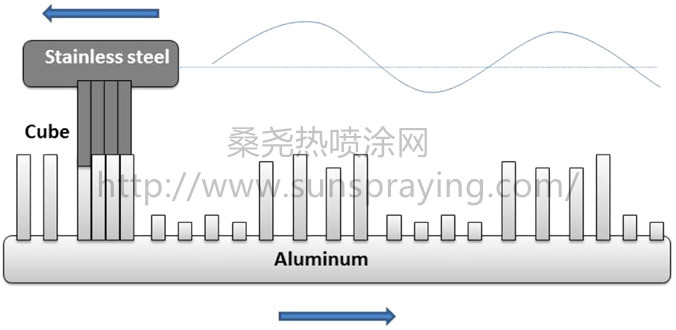

Friction exists when two contacting surfaces slide relative to each other. Material near the surfaces undergo plastic deformation and break away from the body of the material, resulting in surface wear. It has been shown that application of ultrasonic vibrations at the interface of two surfaces in sliding contact reduces the effective friction force between the surfaces. This phenomenon, often referred to as ultrasonic lubrication, is promising in applications in which traditional lubrication methods are unfeasible (e.g., vehicle seats, space mechanisms) or where friction modulation is desirable (e.g., automotive steering or suspension components). Ultrasonic vibrations have been successfully implemented in practical applications. Piezoelectric materials, the transducer elements that typically drive ultrasonic lubrication systems have been incorporated into small control actuators, self-levitating sliding contact bearings, and industrial components, among others. In metal machining and forming processes such as drilling, pressing, sheet rolling, and wire drawing, ultrasonic vibrations have been utilized to reduce the force between tool and workpiece, leading to improved surface finish. Ultrasonic vibrations are usually applied to only one of the two contacting surfaces. The vibration direction can be perpendicular, longitudinal or transverse relative to the macroscopic sliding velocity. Each of the three directions, and combinations thereof, have been studied. For example, Pohlman and Lehfeldt studied the influence of ultrasonic vibrations on friction between lubricated metal surfaces by applying vibrations in all three directions. They determined that ultrasonic vibrations reduce the internal and external friction force in plastic forming processes. Littman et al used a piezoelectric actuator generating vibrations at 60 kHz, making it slide longitudinally on a guide track. Bharadwaj and Dapino also applied longitudinal ultrasonic vibrations to investigate the dependence of friction reduction on macroscopic sliding velocity, normal load, contact stiffness, and global stiffness. Kumar experimentally determined that longitudinal vibrations were more effective at reducing friction force than transverse vibrations and confirmed that the velocity ratio greatly influences the degree of friction reduction. Traditional lubricants are undesirable in harsh aerospace environments and certain automotive applications. Ultrasonic vibrations can be used to reduce and modulate the effective friction coefficient between two sliding surfaces. This paper investigates the relationship between friction force reduction and wear reduction in ultrasonically lubricated surfaces. A pin-on-disc tribometer is modified through the addition of a piezoelectric transducer which vibrates the pin at 22 kHz in the direction perpendicular to the rotating disc surface. Friction and wear metrics including volume loss, surface roughness, friction forces and apparent stick-slip effects are measured without and with ultrasonic vibrations at three different sliding velocities. SEM imaging and 3D profilometry are used to characterize the wear surfaces and guide model development. Over the range of speeds considered, ultrasonic vibrations reduce the effective friction force up to 62% along with a wear reduction of up to 49%. A simple cube model previously developed to quantify friction force reduction is implemented which describes wear reduction within 15% of the experimental data. In this study, a modified pin-on-disc tribometer was built for investigating the effect of ultrasonic vibrations on friction and abrasive wear between stainless steel pins and aluminum discs under a normal load of 3 N. Ultrasonic vibrations generated by a piezoelectric actuator had an amplitude of 2.5 μm and a frequency of 22 kHz. Three different linear speed were considered (20.3 mm s−1, 40.6 mm s−1, and 87 mm s−1) while keeping other parameters unchanged throughout the testing. The friction measurements show that ultrasonic vibrations reduce the effective friction force up to 62%. Consistent with previous studies, the benefit of ultrasonic vibrations diminishes with increasing speed, though 29% friction force reduction was still achieved at 87 mm s−1. Other parameters such as contact stiffness, surface roughness, and materials hardness are known to participate in ultrasonic lubrication. Those parameters will be the subject of a future study. Further, characterization of ultrasonic lubrication will be performed at higher speeds and normal pressures. According to theory, higher ultrasonic power is required to achieve the same degree of ultrasonic lubrication achieved at lower speeds and pressures.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|