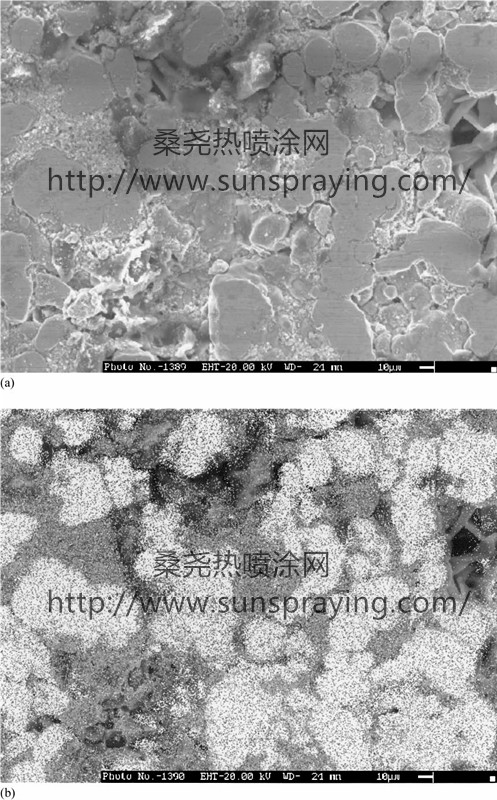

Advances in powder metallurgy technology offers various types of self-lubricating bearings, such as solid lubricant embedded bearings, oil-impregnated bronze, iron, iron–graphite bearing and so on. Interconnected system of pores renders the supply of impregnated oil throughout the entire metal piece. The oil flows through the porous structure and is furnished to the metal surface, providing thereby permanent lubrication. Notwithstanding the temperature limitations of liquid lubricants, oil-impregnated bronzes are used in the low loads/high velocities range only. At the same time, the addition of oil to bearings is prohibitive for various applications, like vacuum systems and electrical motors. In the past few years, inorganic fullerene-like supramolecules of metal dichalcogenide MX2 (M D Mo, W, etc.; X D S, Se), materials with structures closely related to (nested) carbon fullerenes and nanotubes have been synthesized. The size of these hollow nanoparticles can be regulated from about 10 to 150 nm. Recent experiments, in which the IF was used as an additive to oil, showed that IF possess lubricating properties superior to those of 2H platelets in a wide range of operating conditions, in various concentrations and load/speed ratios. However, the slippery nature of these nanoparticles leads to their fast displacement from the contact area, and consequently the efficacy of their lubrication rapidly vanishes. By confining the IF nanoparticles inside a porous and densified solid matrix, their slow release to the metal surface is expected to alleviate both friction losses and wear, while assuring the mechanical integrity of the composite. It is expected that the development of densified powder matrixes incorporating nanoparticles of a solid lubricant with and without oil will allow to develop a new powder composites with largely improved mechanical and tribological properties. The main issue of this work was to check the friction and wear of bronze–graphite powder materials impregnated with solid lubricants and oil. Commercially available WS2 particles (2H) in a shape of platelets and IF-WS2 hollow nanoparticles were used as additive to oil in this study. In the past few years, WS2 and MoS2 nanoparticles (IF) with structures closely related to (nested) carbon fullerenes and nanotubes have been synthesized. It was shown before that addition of a small amounts of such nanoparticles to lubricating fluid largely improve the tribological properties of contact surfaces. In the present work, impregnation of the nanoparticles into a porous powder (bronze–graphite) matrix is demonstrated. The critical point to seizure of the powder matrix impregnated with mineral oil, 2H–WS2 platelets and IF nanoparticles was measured and is 300, 570 and 950 N, respectively. The friction coefficient of the powder matrix lubricated by oil and oil C IF-WS2 was measured. It was found that the addition of the IF nanoparticles in the oil decreased the friction coefficient by 30–50% as compared to the surfaces lubricated by the oil alone. The main effect of IF nanoparticles in comparison to 2H–WS2 platelets appears to be the storage of the nanoparticles for long periods of times within the pores and the gradual release and furnishing to the contact surface. Once released from the pores, IF nanoparticles protect better the rubbed surfaces against straight contact. Bronze–graphite nanocomposites impregnated with oilC fullerene-likeWS2 nanoparticles were shown to exhibit very low friction coefficient and slow wear rate over a wide range of the pressure–velocity (PV) parameter. The critical load for transition to seizure is shown to be substantially higher for the bronze–graphite composite impregnated with IF as compared to the composite impregnated with 2H–WS2 particles (platelets). It is shown that one of the main advantages of the impregnated IF nanoparticles is their long-term storage in the porous media and the subsequent gradual furnishing to the contact surface.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|