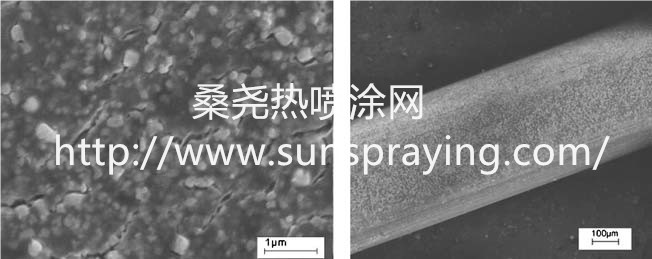

Orthodontics is a dental specialty, which aims to bring about changes in the location of abnormally positioned teeth. In order to move a tooth there is a need for continuous application of mechanical force on the tooth (usually between 100–200 g) which is immediately directed towards the supporting tissues of the teeth, the periodontal ligament (PDL) and the bone. These forces will lead to a well coordinated biological sequence of degradation and regeneration of the PDL, along with bone resorption and apposition, finally placing the tooth in a new position. Tooth movement is directed on a rigid archwire that runs through a slot in the brackets and is held in the slot by an elastic module or a ligature. The movement does not happen in a linear fashion but in a manner of tipping and uprighting motions. A frictional force between the wire and the bracket, which resists the movement of the tooth, accompanies this sliding motion and is referred to as resistance to sliding (RS). Following the application of a force the tooth begins tilting and an angle develops between the archwire and the bracket slot. Above a certain critical angle (hc) the archwire makes contact with the edges of the bracket thereby producing adhesion between the two metallic bodies. At still a higher angle of the archwire (hz) notching sets-in, leading to plastic deformation and periodic steps in the wire that might stop the sliding completely. Overcoming this impediment means using excessive orthodontic load, with 40–60% aimed at overcoming the frictional resistance. The use of excessive force is a major problem in the field of orthodontics. When force is applied on a tooth that needs to be moved, the same force acts on the counter body, i.e. the anchor unit. In most cases the posterior teeth serve as the anchor unit and applying excessive force can cause undesirable movement of these teeth (‘‘loss of anchorage’’) and root resorption of mainly the anterior teeth (incisors). Preservation of the anchorage can be achieved by connecting a number of teeth together or by inserting special intra-oral devices which bond several teeth together. Often the use of an extra-oral appliance is needed to further enlarge the anchorage unit and with these appliances, a problem of patient compliance and possible injury are encountered. Recently, infra-bony insertions of mini-implants which integrate within the bone are used as an anchor unit against the moving teeth. At the completion of treatment the implants are unscrewed from the bone. Numerous attempts were made to overcome this problem, by using wires of a different metal, shape and size, affecting mostly the initial friction forces at angles below hc. Nanoparticles of metal dichalcogenide with fullerene-like structure discovered in the early 90s are known to serve as excellent solid lubricants under various conditions. In order to utilize the properties of the IF-nanoparticles to reduce the friction during the orthodontic treatment there is a need for coating the orthodontic wires or brackets with the nanoparticles. One method of incorporating the nanoparticles into a coating is by composite electroless deposition. Of the variety of metal ions that are in use, the common nickel–phosphorous (Ni–P) films have proven supremacy in corrosion and wear resistance. To set the stage for the archwire experiments, preliminary tribological assays were undertaken using a stainless steel (SS) substrate. Comparative friction tests were undertaken using a ball on flat tribometer. Afriction coefficient l=0.4 was obtained for a flat SS substrate. When a Ni–P film was deposited on the SS substrate l=0.1 was recorded after 50 cycles, but with an uprising tendency and substantial wear. When the composite Ni–P+IF coating was used on the SS substrate, l=0.06 was recorded and only little wear was observed on either the coated substrate or the ball after 200 cycles. Transfer of some IF nanoparticles from the SS substrate onto the ball were observed. These nanoparticles could be easily removed by cleaning the surface with ethanol. In the next stage straight orthodontic wires were cut into short (1 cm each) pieces and glued side by side to form an almost uniform substrate for the tribological tests. Figure shows the scanning electron microscopic (SEM) image of Ni–P+IF coated SS wires. Figure shows the evolution of the friction coefficient for the bare wires and those coated with Ni–P+IF film. While the friction coefficient for the pristine wires increased with time and reached the value of 0.25 after 30 cycles, the friction coefficient declined throughout the experiment reaching the value of 0.05 for the coated wires.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|