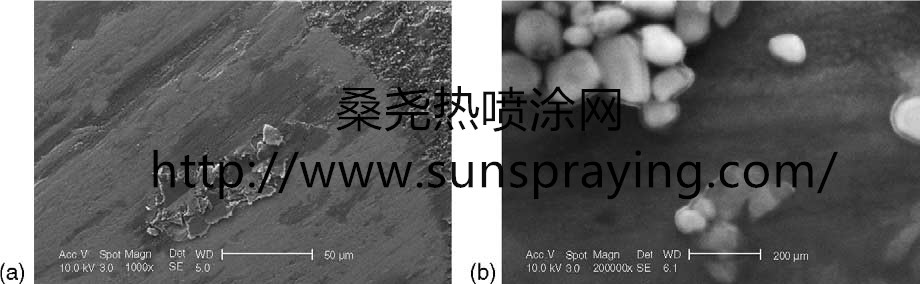

Fullerene-like WS2 (MoS2) nanoparticles (IF) have been studied in the past. Their efficacy as additives for lubrication fluids was demonstrated in a series of tests. These experiments showed that the IF added to oil possess lubricating properties superior to those of 2H platelets in a definite range of operating conditions. The tribological properties of IF in the concentrated contact have been evaluated. It was shown that the IF nanopaticles appear to form a protective film allowing increased load capacity of the rubbed pairs under mixed lubrication. The improved tribological behavior with IF-WS2 was attributed to the decreasing fraction of straight asperity contact in the mixed lubrication regime. It was established that supplying pristine IF nanoparticles through the porous system of the powder materials endows a very high load bearing capacity for the powdered composites. Recent experiments demonstrated the high efficacy of the IF nanoparticles under severe contact conditions. However,the friction and wear properties of the IF nanoparticles under severe contact conditions are currently not well understood, especially in the critical point of transition to seizure. It is expected that the preservation of pristine IF nanoparticles in the clearance between the rubbed surfaces allows to improve remarkably the friction and wear properties of the contact pairs under severe contact conditions. The main objective of the present work is to evaluate the behavior of the IF nanoparticles under severe contact conditions i.e. the transition to seizure. The effect of pristine IF nanoparticles burnished to alumina porous matrix on friction and wear of ceramic pair under high contact pressure is also considered. Fullerene-likeWS2 (MoS2) nanoparticles (IF) have been studied in the past. Itwas shown that the IF nanopaticles appear to form a protective film allowing increased load capacity of the rubbed pairs under mixed lubrication. The main objective of the present work is to evaluate the behavior of the IF nanoparticles under severe contact conditions—the transition to seizure. The effect of the IF nanoparticles burnished to porous alumina matrix on friction and wear of alumina-Si3N4 pair under high contact pressure is also considered. It was shown that when the gap between the contact surfaces is smaller than the size of the IF nanoparticles, there is no effect of the nanopaprticles on the friction force. With load increasing, the IF nanoparticles penetrate into the interface, protecting the rubbed surfaces from a direct contact and thus increase the critical point of transition to seizure. Burnishing of the porous alumina surfaces by the IF solid lubricant nanoparticles provides very low friction coefficient and wear loss under high contact pressure. The IF-WS2 nanoparticles are found to be preserved in the rough summits, fill the valleys, and the pores of the sintered alumina and thus limit the straight contact between the ceramic surfaces. Although the external sheets of the outermost layers of the IF-WS2 nanoparticles were peeled-off, the pristine IF nanoparticles remain in the valleys and pores of the alumina supplying the solid lubricant sheets to the contact area during a long-term test. It was shown that when the gap between the contact surfaces is smaller than the size of the IF nanoparticles, there is no effect of the nanopaprticles on the friction force. The pores, ploughing tracks and the rough surfaces with typical sizes larger than the size of pristine IF nanoparticles allow their supplying to the contact surfaces and thus improve remarkably the tribological properties under severe contact conditions. With increasing load, the IF nanoparticles penetrate into the interface, protecting the rubbed surfaces from a direct contact and thus increase the critical point of transition to seizure. Molecular sheets of WS2 from the delaminated IF nanoparticles, which reside in the valleys of the rough surfaces, cover the contact spots and thus decrease the number of adhered spots at the transition to seizure. Pristine IF-WS2 nanoparticles burnished to the surface of sintered alumina are damaged with a loading, and thin exfoliated sheets in the contact spots limit direct contact between the ceramic surfaces. Burnishing the porous ceramic surfaces by the IF solid lubricant nanoparticles provides very low friction coefficient and wear loss under high contact pressure.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|