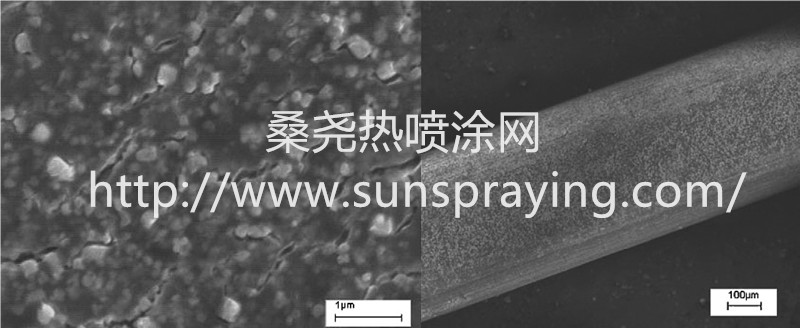

The inorganic fullerene-like tungsten disulfide (IF-WS2) nanoparticles were described first in 1992. It was shown that under certain reducing and sulfidizing conditions, at elevated temperatures, tungsten oxide (WO3) nanoparticles could form nested WS2 fullerene-like nanostructures creating layers that resemble an onion or a nanotube. These nanoparticles are constructed of multiple layers which can be represented as a sandwich of covalently bonded S–W–S moieties within the plane. The layers are weakly connected through van derWaals forces only. The size of these nanoparticles ranges from 20 to 200nm depending on the WO3 precursor size. It is known that WS2 and MoS2 particles with layered structure (platelets) provide good lubricity. Synthesis of fullerene-like WS2 nanoparticles has allowed remarkable improvement of friction and wear properties under different contact conditions. Low friction and wear is associated with the penetration of solid lubricant WS2 nanoparticles into the interface between rubbed surfaces. As the load between the bodies increases, the nanoparticles gradually deform and exfoliate, leaving nanoplatelets of the sandwiched material to coat the asperities at the interface. The weak forces, between the thin sheets of the exfoliated nanoparticles, allow a very low shear force sliding motion between the two contacting bodies. Sliding a tooth along an orthodontic wire is acommonclinical procedure, especially during closure of spaces in the dental arch.Whenever sliding occurs, a frictional type of force is generated between the wire and the orthodontic bracket which is bonded on the tooth. The resistance caused by the friction is characterized by static and kinetic types of force. Static friction is the force required to produce the initial toothmovement and is always higher than the kinetic force. Since the orthodontic force must overcome that frictional resistance (which is nearly twice the force level required to cause bone remodeling to allow tooth movement) minimizing friction will result in reduced levels of the clinically applied orthodontic force. Such a reduction might improve both anchorage control and direction of tooth movement. It can also reduce the risk of apical root resorption and may even shorten the treatment duration. Up to date, attempts were mostly directed at reducing this friction by altering bracket design, using different types of alloys and surface treatments of the wires. These attempts were successful to some extent. The current study was designed to reduce this friction by using a novel method of coating orthodontic stainless steel wire with IF-WS2 nanoparticles that are known for its high lubricating properties. Thus, the aims of this study were first to coat stainless steel wires with IF-WS2 incorporated into a nickel–phosphorus (Ni–P) matrix which acts as a slow release mechanism for the nanoparticles. Second, to evaluate the efficacy of the fullerene-like coated wires in reducing friction in an in vitro tooth sliding model. Third, since a certain amount of the nanoparticles was likely to be released from the coating, or exfoliate during motion, it was very important to examine the coated wires after sliding, to assure the adhesion properties of the IF-WS2 in the matrix layer. The presence of IF-WS2 is a prerequisite for proper lubrication during motion. Objective. To reduce friction between orthodontic stainless wires and bracket by coating the wire with nickel–phosphorous electroless film impregnated with inorganic fullerene-like nanoparticles of tungsten disulfide (IF-WS2) which are potent dry lubricants. Methods. Coating was preformed by inserting stainless steel (SS) wires into electroless solutions of nickel–phosphorus (Ni–P) and IF-WS2. The coated wires were analyzed by SEM (scanning electron microscope) and EDS (energy-dispersive X-ray spectrometer) as well as by tribological tests using a ball-on-flat device. Friction tests simulating archwire functioning of the coated and uncoated wires were carried out by an Instron machine. The adhesion properties of the coated wires after friction were analyzed by a Raman microscope. Results. SEM/EDS analysis of the coated wires showed clear impregnation of the IF-WS2 nanoparticles in the Ni–P matrix. The friction coefficient measured by the ball-on-flat tribometer was significantly reduced (from 0.25 to 0.08). The friction forces as measured with the Instron on the coated wire were reduced by up to 54% (4.00 N±0.19 uncoated vs. 1.85 N±0.21 coated). Raman spectra showed that even after extensive friction tests the Ni–P with the IF-WS2 nanoparticles is attached to the underlying stainless steel wire. Conclusions. It is proposed that the wires coated with these nanoparticles might offer a novel opportunity to substantially reduce friction during tooth movement. A fewtests undertaken to evaluate the toxicity of the fullerene-like nanoparticles have provided indications that they might be biocompatible.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|