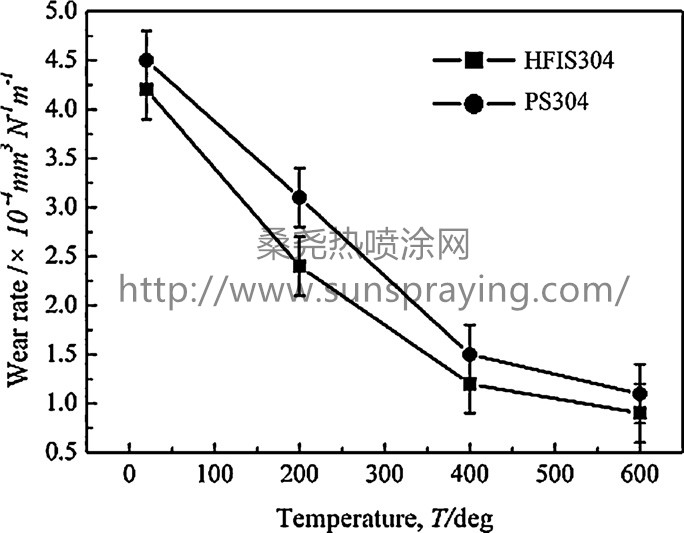

A series of plasma-sprayed high temperature self-lubricating coatings such as PS212 and PS300 with a working temperature limit up to 800◦C have been developed by NASA. PS304, a new coating composition, is comprised of a Ni80Cr20 matrix (60 wt%) combined with Cr2O3 (20 wt%) as a hardening phase and the solid lubricant additives Ag (10 wt%) and eutectic BaF2/CaF2 (10 wt%). Silver acts as a thermochemically stable solid lubricant at a relatively lower temperature range. from room temperature to approximately 450◦C. The fluorides offer effective lubricating above 400◦C . However, plasma-sprayed PS304 coatings consist of flat platelike lamella. Interlamellar bonding is predominantly by mechanical keying, thus the true interfacial contact area is only a fraction of the nominal area [4]. This results in the porous microstructure (15 vol.% porosity) and the low hardness (less than 400 MPa). The existence of interconnected porosity and segmented cracks in PS304 coatings not only affects the mechanical properties, but also reduced the wear resistance of the coatings. Furthermore, at room temperature, the wear rate and friction coefficient of PS304 is much high resulting in coating rapid failure. The wear resistance and mechanical properties of coatings are strongly influenced by the size and distribution of the lubricating phase. It has been found that the wear resistance of nanostructured coating is higher than that of conventional coating. The high-energy ball milling technique, which is an effective method for producing nanocrystalline powders has been considered as a powerful technique for synthesizing numerous composite materials. High-frequency induction sintering (HFIS) is a rapid sintering method which was developed recently for the fabrication of nanostructured composites. During the HFIS, a large current will be induced in the sample. As a result, the nanostructured sample can be sintered uniformly and rapidly. So in this study, nanocrystalline composite powders were fabricated by a high-energy ball milling. Furthermore, a high-frequency induction sintering was used to produce HFIS304 composites with fine grains. The microstructure and tribological properties of HFIS304 composites were investigated. The composite HFIS304 powders were produced by high-energy ball milling technique. Then the HFIS304 coatings were prepared by cold isostatic pressing and high-frequency induction sintering (HFIS). The microstructure of HFIS304 was fine and dense, the size of Cr2O3, BaF2/CaF2 particles was below 1m, and that of Ag particles about 1m. The tribological properties of HFIS304 composites against Inconel X-750 were examined in the temperature range from room temperature to 600 ◦C. The wear resistance and friction coefficient of the HFIS304 were superior to that of the PS304 in the temperature range from room temperature to 600 ◦C.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|