Ships and offshore structures are exposed to harsh marine environments, and maintenance and repair are becoming increasingly important to the industry and the economy. When a structure is composed of stainless steel 304 (STS304), protecting this material against corrosion is vital to ensure the structure’s structural integrity. Since many marine structures are fixed under sea water, inspection and maintenance costs further emphasize the necessity for corrosion resistance. Fractures within these marine structures are mainly related to corrosion and welding.1–7 Methods of protection against corrosion can generally be divided into two groups: anodic protection and cathodic protection. Anodic protection is limited to the passivity characteristics of a material in its environment, while cathodic protection consists of methods such as sacrificial anode cathodic protection and impressed current cathodic protection (ICCP). Sacrificial anode methods using Al and Zn alloys are widely used for marine structures and vessels intended for use in sea water. ICCP methods are also widely used in marine environments, but tend to generate problems related to hydrogen embrittlement caused

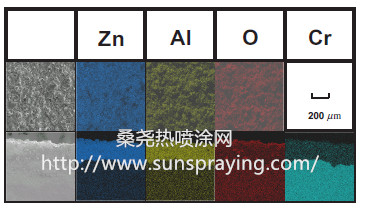

by hydrogen gas generation. Therefore, it is very important to determine the optimal method of application to achieve ICCP. Thermal spray coating technology has been adapted to prevent corrosion in small-ship shaft systems. While shaft systems commonly employ STS304, STS316, and STS630, we selected STS304 for this study based on electrochemical and economic factors. Thermal spray coating provides a sacrificial anode based on differences in galvanic potential.8–12 between stainless steel and its coating material, thereby extending the lifespan of the shaft. In this investigation, Zn,Al, and Zn+15%Al thermal sprays were adapted to provide corrosion resistance. Damage to a coating results in the formation of a galvanic cell between STS304 and the coating, allowing the coating to preferentially corrode. STS304 can be protected against corrosion when exposed to sea water through a thermal spray-coated application of a sacrificial anode. The Tafel experiments revealed that Al-coated specimens had the lowest corrosion current densities. As the corrosion potential decreases with increasing corrosion current density, we estimated the characteristics and lifetime of the protective thermal spray coating layer in the galvanic cell formed by the thermal spray coating layer and STS304.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|