THERMAL spray coatings are often used to provide thermal barriers in turbine engines and internal combustion engines, and to repair expensive worn machine and engine parts. These applications require that the coating remain bonded to the component. Although thick coatings would appear to provide longer service life, certain problems are unique to thick coatings. Specifically, early debonding of thick coatings can reduce service life and preclude any advantages. Bond strength tests and in-service applications of coatings with different thicknesses have shown that bond strength and service life decrease with increasing coating thickness. Howell, in a study concerned with metal coatings applied to concrete, reports that increased coating thickness results in decreased bond strength. Results givenby Unger and Grossklaus (Ref 1) show that for some coatings the bond strength of a thick coating applied to stainless steel or titanium can be as low as one-third of the bond strength of a thin coating. Woods (Ref 3) presents data for coatings on internal combustion engines that indicate a trend of decreasing bond strength and decreasing number of cycles to failure with increasing coating thickness. One credible hypothesis to explain this behavior is that residual stresses contribute to the reduced bond strength for thicker coatings. Residual stresses are inherent in thermal spray coatings; furthermore, such stresses are often tensile because thermal spray coatings are applied at a high temperature to a cooler substrate. Upon cooling, the coating will contract more than the substrate. Because the substrate constrains the coating from contracting, the coating has tensile residual stresses after cooling. The literature indicates that tensile residual stresses are a factor in fracture. For example, Rybicki and Stonesifer have shown that tensile residual stresses clearly have an effect on reducing he fracture strength of a pressure vessel for linear elastic conditions. Another finding, related to the contribution of residual stresses to coating debonding, is that in-plane tensile stresses, acting in the same direction as the residual stresses in the thermal spray coatings, cause free-edge debonding of laminated plates. The in-plane tensile stresses in the laminate create a peel-back mechanism that can lead to debonding at the edge of coated test specimens. However, little work has been performed to show that residual stresses have an effect on the

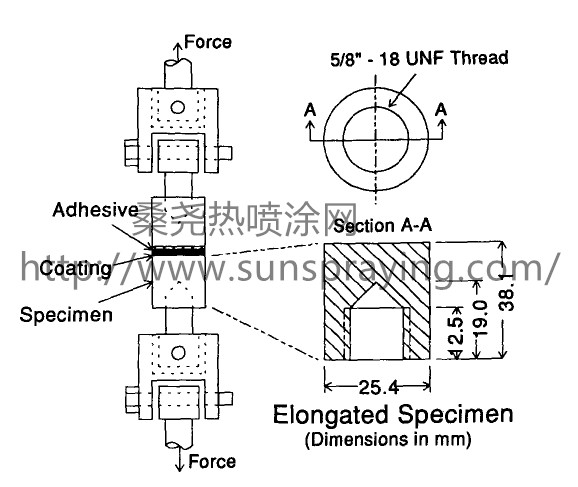

bond strength of thermal spray coatings. The mechanism concerning how residual stresses interact with coating thickness to contribute to reduced bond strength is of interest. This behavior is called the "free-edge effect" and occurs in the debonding of laminated composite materials (Ref 7). The Appendix to this paper describes the free edge effect. In previous work, a fracture mechanics approach was used to predict the bond strengths of different coatings using an improved ASTM C 633-79 test specimen. This approach was applied to an aluminum oxide coating, a tungsten carbide coating, and an adhesive. The goal of the present work is to investigate the effects of coating thickness and residual stresses on bond strengths of thermal spray coatings. The approach is to select a commonly used coating system and to characterize the residual stresses and bond strengths for a range of coating thicknesses. The fracture mechanics analysis is extended to include residual stresses and is applied to the bond strength data to examine possible mechanisms linking residual stresses and coating thickness to the observed decreased bond strength behavior. Results are compared with bond strength data available in the literature. The long-range goal of this work is to increase the service life and operational efficiency of thick thermal spray coatings by improving the residual stress state in the coatings. Bond strength test data show that the bond strength of thermal spray coatings decreases with increasing coating thickness. The effect of coating residual stress on decreasing bond strength was investigated. Residual stresses were determined experimentally for four coating thicknesses using a modified layer-removal method. Residual stress measurements indicate that residual stresses are minimally influenced by coating thickness for wire-arc sprayed nickel-5 aluminum coatings on AISI 1018 steel. It appears that tensile residual stresses in the coating cause the degradation of bond strength with increasing coating thickness. Apossible mechanism for this effect is described in the Appendix to this paper. Debonding was simulated using a fracture mechanics approach. It was shown that the effects of residual stress on bond strength for different coating thicknesses could be predicted using a fracture mechanics analysis that included the measured residual stresses in the coatings. Based on the fracture mechanics results, the decreasing bond strength behavior of the coatings can be explained without assuming an increase in residual stresses as the coating thickness increases. The fracture mechanics results also suggest that by changing residual stresses from tension to compression, or to lower levels of tensile stresses, bond strengths of thicker coatings can be improved.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|