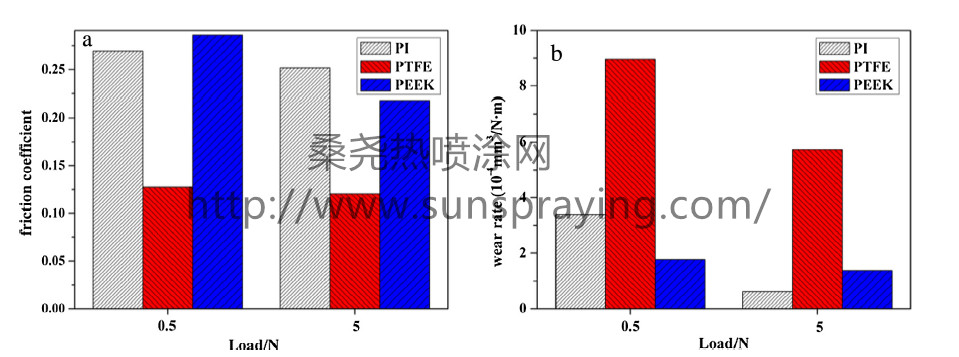

With the urgent attention to aerospace industries around the world, the demand for materials used in the harsh space environment has increased. The environmental conditions materials encounter in space include atomic oxygen, ultraviolet irradiation, proton and electron irradiation, high vacuum, and thermal cycling. When a satellite runs in low earth orbit, it experiences thermal cycling which can induce thermal degradation of structural materials. Thermal cycling is introduced while the spacecraft passes in and out of the earth’s shadow. The cryogenic temperature in the shadow limits the use of metal and conventional lubricants( oil and grease) in friction units, while polymers, potential self-lubricating materials, require special concern in cryogenic applications for their favorable low thermal and electrical conductivity, and permeation characteristics. Polymers and polymer composites have been widely investigated for mechanical and tribological properties at cryogenic temperatures. Poly(ethersulfone) (PES) containing multi-walled carbon nanotubes (MWCNTs) has been reported to be beneficial for the improvement of cryogenic mechanical properties of epoxy resins. Michael et al. found that epoxy mixes exhibit viscoelastic behavior at room temperature and the frictional properties show time and composition dependence, while at cryogenic temperatures when the resins are in the glassy state, no dependence of the friction coefficient on time or composition is found. McCook et al. reported a monotonic increase in friction coefficient as the sample surface temperature was decreased from 317 to 173 K for PTFE composites. They related the friction coefficient of polymers with their viscoelastic behavior by modeling friction performance using an adjusted Arrhenius equation and they believed the breaking of van der Waals bonds was possibly relevant to the frictional behavior over the experimental temperature. Yukhno et al. studied the tribological properties of polymerbased solid lubricant coatings at 293, 120 or 77 K in vacuum. They found that the coefficient of friction was somewhat higher at low temperatures. But the effect of temperature decrease on the wear life of solid lubricant coatings is still ambiguous. The synergistic effect of vacuum and thermal cycling on composites are studied by Park SY and they found internal damage on the composites surface had been found after 500 cycles which further resulted in the deterioration of thermal and mechanical properties. Theiler et al. studied the tribological behavior of PTFE composites at cryogenic temperatures. With temperature down to 77 K the friction coefficient of PTFE decreased, but did not drop further down to 4.2 K. And they also stated that the cooling ability of the cryogenic liquids played a vital role on the tribological performance of PTFE. In their following works they investigated the friction and wear behavior of graphite or MoS2 filled PEEK composites at different temperature in vacuum. At 40℃ the sliding behavior of MoS2 filled PEEK composites showed lower friction coefficient and wear rate. Moreover, the friction coefficient was steady at low temperature while it fluctuated obviously at room temperature. Since transfer film is not easy to form on the steel ball at low temperatures, the real surface area in contact between steel ball and polymer disk determines the friction coefficient. Higher hardness appearing at cryogenic temperature results in decreasing contact area between the friction pairs. Thus, the friction coefficients are lower for all the three polymers at cryogenic temperatures than at room temperature. Wear rates decrease as the temperature decreases due to the poor mobility of molecules at lower temperatures. As the test temperature (50 ℃) is far below the polymer glass transition temperature (Tg), the friction coefficient shows little dependence on sliding speed. Adhesion is a predominant wear mechanism for PTFE. According to elastic contact theories and the definition of friction coefficient, the influence of contact pressure and the increasing real contact area generated by elastic deformation of surface asperities determine the friction behavior. The friction coefficients of PI, PTFE and PEEK fall as the load increases.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|