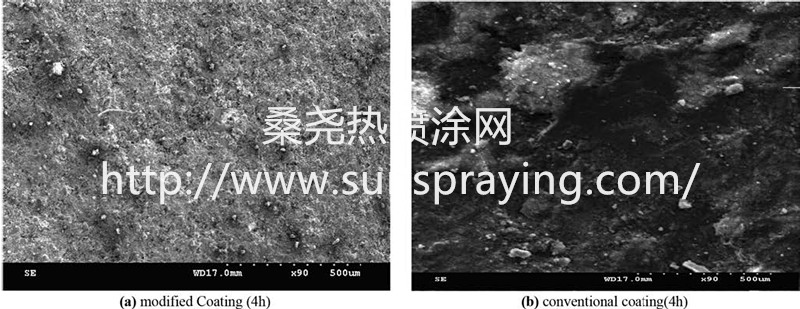

With the continuous advancement of nanotechnology, and the superiority of nano-materials as compared to their traditional counterparts, the combination of nano-materials and surface coating technology is conducive to expand the application of nano-materials and meet the performance requirements of components under more onerous or complex conditions. Nano-structured coatings, composed of nano-structured powders using a variety of thermal spray technologies, show excellent performance. Existing research indicates that with the nano-material as a coating, using corresponding methods, a nano-composite coating developed with a certain thickness on the surface of a metal substrate achieves the desired nano-crystallisation, thus imparting to the metal new features better able to meet certain specific service life requirements. Plasma thermal spraying technology has attracted attention amongst researchers who have used this to prepare a variety of nano (or nano-metre-contained) coatings incorporating nano-particle surface modification. Based on these property modifications, some researchers show that , by applying the nano-particle modification technology to the development of wear-resistant coatings, and by applying the nano-particles to such coatings by thermal spraying technology, they can achieve a modification of the coating which makes the structure denser and more uniform. Therefore, the wear-resistant properties of coating have been improved and the friction coefficient has been effectively reduced. Currently, there are few researchers concentrating on the study of the process and performance of coatings doped with nano-particles by laser re melting incorporating simultaneous surface texturing, and very few studies of their high-temperature tribological properties. This research used laser re-melting technology and surface texturing techniques to prepare a KF301/WS2 nano-modified coating with a round, pit-type texture: its im was to explore the influence of this new composite method on the organisation and structure of sprayed coatings, as well as the evolution rules governing their high-temperature tribological properties. The laser re-melting technology and surface texturing technique were combined to compositely prepare the KF301/WS2 nano-modified composite coating with a rounded, pit-type texture. These nano-particles could effectively strengthen the coating micro-structure, achieve modification of the coating and make the structure denser and more uniform, thus reducing its through-hole rate and opening passage rate. The nano-SiC particles influenced the friction factors and wear loss of coatings with rounded, pit-type textures to some extent. The tribological properties of the modified coating were better than those without modification. When the friction and wear processes were in a stable state, the friction coefficient decreased by 13 per cent, while the wear loss declined by 45.9 per cent.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|