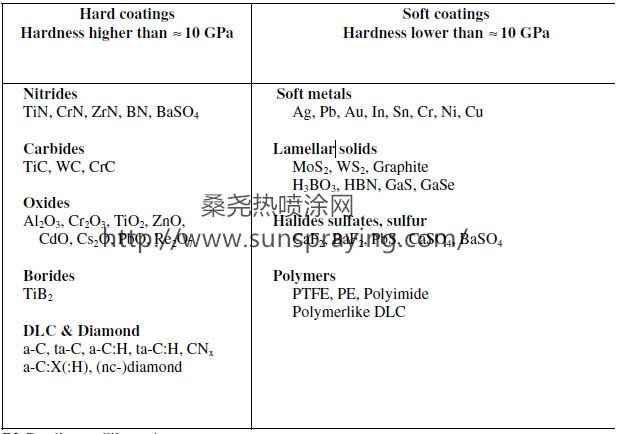

Naturally, certain solid materials possess low shear strength and when applied on a sliding surface, they can lower friction and wear. These materials are referred to as ‘‘solid lubricants’’. Based on their physical, chemical, structural, and mechanical properties, they can be classified into several sub-categories. For the sake of simplicity, we will divide them in two broad categories: soft (hardness less than 10 GPa) and hard (hardness more than 10 GPa) solid lubricants .The hard solid lubricants exhibit higher wear resistance in addition to lower friction when compared with soft lubricants, which can provide low friction but not always high wear resistance. Hard solid lubricant coatings include some of the carbon-based coatings (such as diamond and DLC) and certain oxides. Soft solid lubricant coatings include polymers, soft metals, halides and sulfates of alkaline earth metals, and the well-known lamellar solids, including transition-metal dichalcogenides, graphite, and boric acid. Most of these self-lubricating materials have been extensively studied in recent years, and some of them have been further optimized to provide better lubricity when used under specific conditions or in environments such as high temperatures (see excellent reviews in). Oxide based materials are generally hard to shear at room temperature, but some of them become highly shear able and hence can provide fairly low friction coefficients at elevated temperatures. These oxides are often referred to as ‘‘lubricious oxides’’. Recently, Erdemir proposed a crystal-chemical model to classify these oxides on the basis of their lubrication performance and operational limits. Efforts to optimize these and other solid lubricants are still in progress. However, on the basis of the fundamental understanding as well as modeling approaches, great strides are being made in the formulation of novel solid lubricants

that can meet the increasingly stringent operating conditions of future tribosystems. For example, Csbased oxides were reported to be very promising for lubricating Si-based ceramic components at high temperatures. At 600℃, friction coefficients of 0.02–0.1 have been reported for Cs2O-lubricated Si3N4 ceramics. During sliding at high temperature, a mixed oxide layer consisting of Cs2O and SiO2 was found and believed to be responsible for low friction. As will be elaborated later (see Section 4 of this paper), new formulations and exotic coating architectures (nanocomposites, alloying/doping, superlattice, gradient, etc.) have been used to produce various film structures to achieve better performance and durability in solid lubricant films. However these developments did not prevent the emergence of new ‘‘single’’ structures or original concepts in solid lubrication. Let us first focus our attention on evolution of single and multicomponent solid lubricant films and then review the progress in other related products and processes.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|