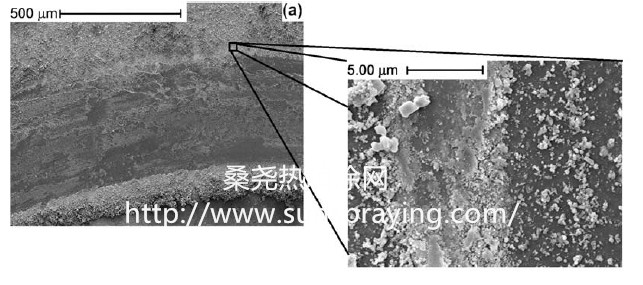

Research on cesium oxythiomolybdate, Cs2MoOS3, was initiated as a response to the requirement for a high temperature solid lubricant for lightweight single-use engines. These engines would most likely use ceramic bearings. Ceramics are a natural choice for engine components due to their lower density, higher melting points, and greater oxidation resistance than typical metals. In aerospace applications, silicon nitride became a leading candidate for ceramic bearings because of its excellent high temperature properties. Lubricants for these bearings were required for operation between -50 and +800℃. Cesium oxythiomolybdate has been shown to be an effective high temperature solid lubricant when used in a coating with a sodium silicate binder, giving a coefficient of friction of below 0.2 at 650℃. A primary concern in using Cs2MoOS3 as a lubricant has been its thermal instability above 200℃.Ordinarily, thermal stability of a lubricant over the entire application temperature range is required. However, since Cs2MoOS3 performs well at elevated temperature, and understanding its oxidation has been the subject of research. It has been previously shown that oxidation of Cs2MoOS3 powders alone is complex, leading to a variety of products at 600–800℃ including Cs2MoOS3 , cesium oxides, Cs2MoOS3, other complex cesium molybdates, MoO3 , and other molybdenum oxides. Cs2MoOS3 provided good lubrication on all substrates tested between approximately 300 and 600℃ by oxidizing to Cs2MoOS4, MoO3, and other oxides. Coefficients of friction were below 0.2 on the oxide and Inconel substrates at 600℃, and good wear protection was provided. The lubrication mechanism was oxide softening. Cs2MoOS3 is an excellent lubricant on Si3N4 substrates between 600 and 750℃, and on SiC substrates between 500 and 600℃, with coefficients of friction below 0.1. Wear protection was also excellent under these conditions. This is due to the unique glass formation lubrication mechanism. First, a silica scale is formed on the surface of the substrate, followed by diffusion of melted cesium oxides into the silica, creating a low shear strength glass with an optimum

viscosity for lubrication. Diffusion of the film into the substrate and the continuous formation of the cesium silicate glass in the wear track accounted for the longevity of the coating.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|