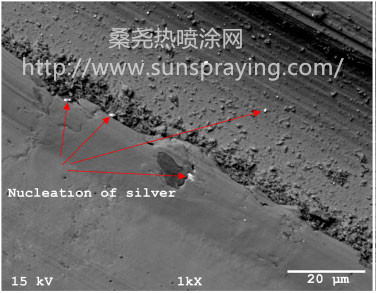

Silver as a new and specific lubricant material is a good candidate for lubrication at low and high temperatures. Particles are co-deposited within Ni–P matrix by electro less composite plating to produce Ni–P–Ag composite coating. there are a few loose bonding particles on the surface of the composite coating whereas they could not be embedded completely in Ni–P coating. By growth of Ni–P coating, silver particles with poor bonding are fully interlocked in Ni–P matrix. From viewpoint of co-deposition mechanism, silver micro sized particles have high surface electric charge in chemical solution and the reduction of nickel ions can be quickly taken place on the surface of silver particles during composite plating. Low hardness of silver particles (y251 HV) leads to easier plastic deformation during microhardness test. On the other hand, heat treatment can improve the hardness via precipitation hardening. Therefore, heat treated coatings will have higher hardness than as plated coatings. Entrapment of silver particles in Ni–P matrix could increase the lubrication and wear resistance of Ni–P coating at room and elevated temperatures. Silver could diffuse and nucleate on the surface of Ni–P–Ag composite coating during high temperature sliding wear and it could also act as a self-lubricant material in nanocrystalline Ni–P–Ag composite coating. Abrasive wear was dominant mechanism in degradation of heat treated Ni-P and Ni–P–Ag coatings. Silver particles could reduce the fluctuations of friction coefficients and also, they decrease the average values of friction coefficients at room and high temperatures. So, Ni–P–Ag composite coating has the suitable capabilities in high temperature sliding applications such as aerospace industries.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|