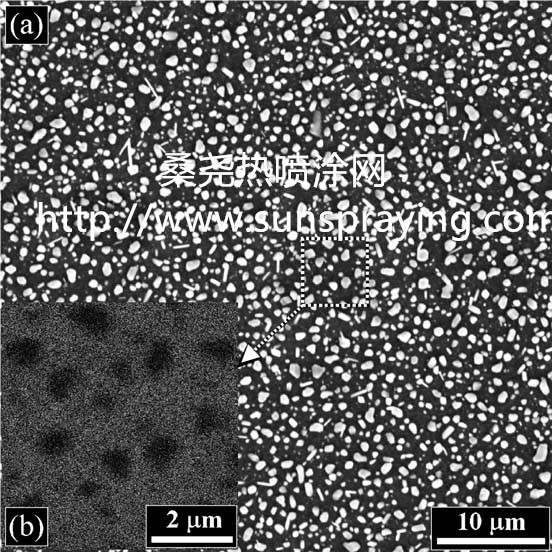

Transition metal (TM) nitride coatings are of considerable interest due to their high hardness and mechanical strength, chemical inertness, and high-temperature stability. CrN coatings show promise for high-temperature applications, as they exhibit good thermal stability and oxidation resistance , as well as promising tribological properties. Soft metal coatings exhibit low shear over a large temperature range, however,high wear, plastic deformation, and gross plowing during sliding causes increasing friction and irregular surface topographies.Several studies have focused on combining multiple materials in a single coating in an attempt to circumvent the shortcomings of individual high-temperature lubricant materials, with the primary method being to combine a hard, wear resistant phase with a lubricating solid, including composite structures such as Ag/BaF2–CaF2 in Cr oxide and Ag in TiC, as well as layered structures such as lubricious oxides on metallic and ceramic coatings and MoS2 over CrN, and adaptive coatings that combine lubricating phases which operate at different temperatures. Composite coatings consisting of a CrN matrix and an embedded Ag solid lubricant were co-deposited via reactive magnetron sputtering. However, co-deposition of Ag leads to a 002 preferred orientation due to a suppressed growth on the rougher 111 surfaces. Segregation within the columnar microstructure leads to a phase separation of the CrN matrix and the Ag solid lubricant. Annealing experiments demonstrate that Ag is mobile in the CrN matrix for coatings with 12 at.% Ag. The Ag diffuses to the surface and forms uniformly distributed agglomerates which increase in size with annealing time, annealing temperature, and Ag content of the coating. The diffusive transport increases rapidly with Ag content. This is attributed to a higher connectivity of Ag-filled grain boundary regions which are expected to form between crystalline CrN columns and to offer an ideal segregation and diffusion path for Ag. The coating with the highest Ag content (22 at.%) exhibits the lowest friction coefficient and the best wear resistance at room temperature.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|