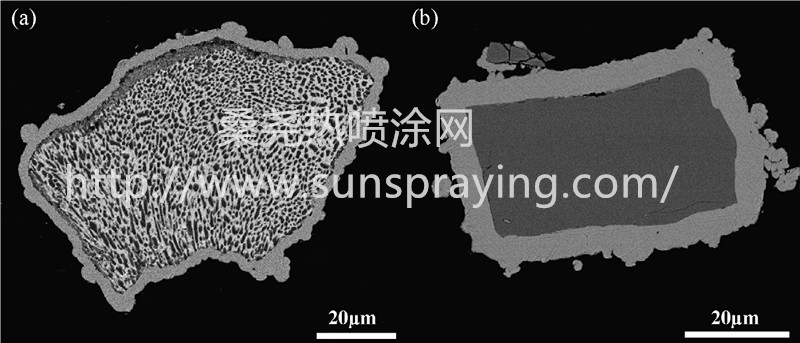

Thermally sprayed Cr3C2–NiCr cermet coatings have been widely used for high temperature wear resistance and corrosion resistance applications in various industrial applications such as power generation industry, gas turbines, oil and steel industries,etc. However, the counter materials sliding against Cr3C2–NiCr coatings exhibit significantly high wear rates dueto the high sliding coefficient of friction and high hardness of Cr3C2–NiCr coatings, which significantly limits the application on rotation devices and other places. In order to reduce the coefficient of friction and improve the tribological properties of this kind of wear-resistant hard coatings, soft noble metals (Au, Ag etc), inorganic fluorides (LiF2, CaF2, etc) and some metal oxides (NiO, MoO3, Cr2O3, etc) have been employed as solid lubricants in numerous studies. It has been found that BaF2/CaF2 eutectic can significantly improve the tribological properties of wear-resistant hard coatings because of its lower melting point and shear strength as compared to a single fluoride, and it has been extensively used as a solid lubricant at elevated temperatures. Using the chemical-coated method and alloying process,BaF2·CaF2 eutectic and Cr3C2 powders cladded with NiCr alloy

were prepared. The resulting NiCr/Cr3C2 and NiCr/BaF2·CaF2 particles were then used as a hard wear-resistant phase and high temperature solid lubricant to prepare NiCr/Cr3C2–BaF2·CaF2 self-lubrication wear-resistant coatings by plasma spray.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|