During the last few decades, metallic glasses have attracted much attention because of their unique combinations of mechanical, physical and chemical properties. However, high cooling rates are generally required for the formation of amorphous phase from the liquid state, resulting in small thickness or diameter sections in the form of powders, ribbons or wires, which greatly restricts their applicability as prospective structural materials. In the nineties, bulk metallic glasses (BMGs) with high glass forming ability and wide supercooled liquid region before crystallization have been developed in a number of alloy systems, which required critical cooling rate of 1–100 Ks−1 for glass formation with large dimensions ranging from millimeters to centimeters. Nevertheless, these BMGs usually exhibit no plastic deformation after yielding and no work hardening during room temperature deformation due to the formation of highly localized shear bands, which significantly limits the range of possible applications as engineering and structural material. To alleviate this case, focusing on their unusual attributes of wear and corrosion resistance, these materials will be more attractive as coatings to withstand aggressive environments.

Fe-based amorphous metallic glasses are considered to be extremely viable candidates as surface protective coatings owning to their high crystallization temperature, superior corrosion and wear resistance, good magnetic properties, and relatively low material cost. However, amorphous phase is a non-equilibrium phase, so alloys with high glass forming ability (GFA) would be favorable for forming and retaining fully amorphous phase coatings via thermal spraying processes. Recently, a series of Fe-based bulk metallic glasses with high GFA have been found in Fe–(Cr, Mo)–(C, B) alloy system, leading to obtain amorphous metallic coatings more easily for satisfying engineering needs. In this paper, a Fe48Cr15Mo14C15B6Y2 alloy, with high GFA and excellent corrosion resistance, was selected to produce amorphous phase coating through HVOF spraying method. The microstructural characteristics of the amorphous coatings obtained under different spraying parameters were investigated, and the comprehensive corrosion behavior of the coatings in different solutions were also examined.

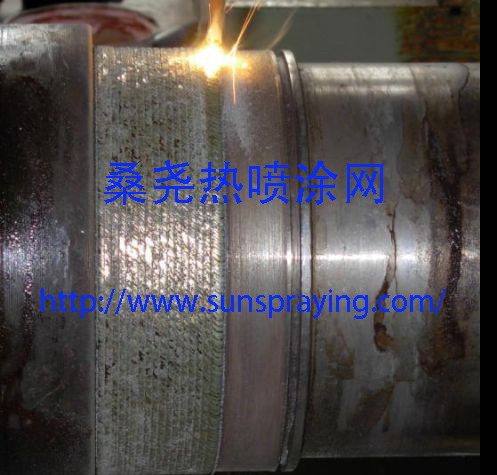

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|