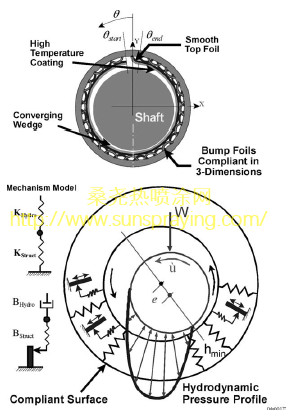

Foil bearings are particularly attractive for systems where conventional oil-lubricated or rolling element bearings are unsuitable due to temperature, speed, working fluid or any combinations thereof. Since foil bearings are oil-free and can operate with ambient air, they are also environmentally friendly solutions for systems where lubricant contamination would be problematic. Applications now possible for foil bearings include aircraft gas turbine engines, auxiliary power units, micro turbines, pumps, compressors, cryogenic turbo expanders and turbochargers, to name a few. Recent advances in foil bearing design have resulted in significant improvements in load capacity, damping, stiffness and high temperature performance. The construction of a compliant foil bearing consists of two parts: a smooth top foil, which constitutes the bearing surface; and a flexible corrugated foil strip formed by a series of bumps to provide resilient support to this surface. The bump foils and top smooth foil provide the mechanical or structural support; the other is its hydrodynamic action resulting from the fluid film (air) between the runner or journal and top foil. The bump foil strip is welded or otherwise fixed at one end of the bearing housing with the other end free. Consequently, the bumps near the free end have a higher deflection, whereas the fixed end has a higher stiffness. Because a compliant foil bearing surface will deform as hydrodynamic pressure is generated, the bearing can be constructed to deform in an advantageous manner for a particular application, be it high load capacity, high-speed operation or stability. This two level construction provides a well-damped, low power loss, oil-free shaft support capable of adjusting to significant misalignment as well as thermal/mechanical shaft and housing deformations. By its very nature, the design also permits the bearing or seal to be tailored to each application for optimal performance through changes in geometry, construction, materials and special coatings. Although there is no sliding contact in the steady state operation of the foil bearing, contact between the foil and journal surfaces will occur at startup and shutdown and occasionally during overload situation, which, under high temperature conditions, limits the life of the low-friction coating, and thus the bearing. The lack of effective high temperature solid lubricant coatings and/or alternate materials currently limits the use of foil bearings to operating temperatures below 300 ℃. Therefore, reliable, long-life, high-temperature materials and coatings are necessary to transition these advanced bearing and seal technologies from ambient temperature applications to the extreme temperature environments found in gas turbine engines.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|