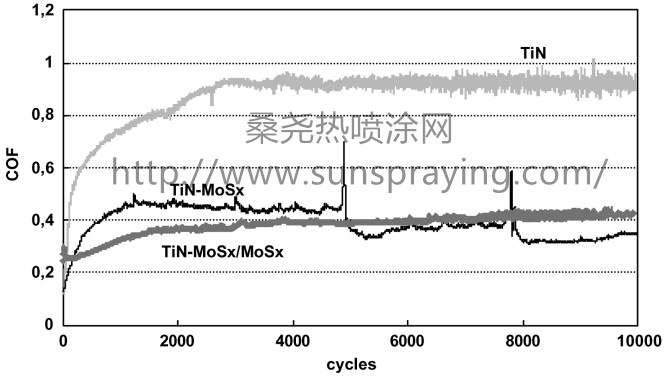

Coatings are widely used to improve the performance of industrial tools. Depending on the application, a whole range of coatings is available. From hard wear resistant coatings for drilling, milling or forming applications, to soft lubricating coatings for applications where fluid lubrication is forbidden (food, clean rooms ) or where a low coefficient of friction (COF) is necessary (bearings, moving contacts). Today, the industry has a strong interest in multicomponent coatings, combining wear-resistance with a low COF. Different coatings have been designed and are described in the literature trying to meet the demands. Roughly, they can be divided in three groups: (1) hard wear-resistant coatings with a solid lubricating top-layer, (2) solid lubricating coatings with metal additions and (3) hard wear-resistant coatings with clusters of a solid lubricating phase spread throughout the coating. Coatings from the first group have shown an improvement limited in time because of the short lifetime of the soft lubricating top-layer. The second group also showed an improved lifetime and hardness but it is not possible to reach high hardness because of the soft lubricating matrix. Coatings from the last group have shown promising results. Because the lubricating phase is spread throughout the total thickness of the layer, the lubricating effect is maintained during the entire lifetime of the coating. The research presented in this work shows mechanical and tribological results of multicomponent coatings TiN–MoSx compared to standard TiN both deposited using a combined physical vapour deposition (PVD) installation and analysed with the same equipment. Research has been performed to design a multifunctional coating combining TiN with MoSx resulting in a wear-resistant coating with a low coefficient of friction (COF). The coatings are deposited by a combined physical vapour deposition technique of Egun evaporation and magnetron sputtering in a BAI640 equipment. Pin-on-disk (POD) measurements at approximately 50% RH against a corundum (Al2O3) ball show a significant decrease in COF compared with the results for a standard TiN coating. The incorporation of a soft phase in the TiN matrix did not lead to a decrease in hardness. The combination of a low COF and high hardness results in a decreased wear rate approximately 20 times lower in POD and 500 times lower in fretting compared to the standard TiN coating. The performance of the composite coating is tested in a drilling application and shows an increased lifetime.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|