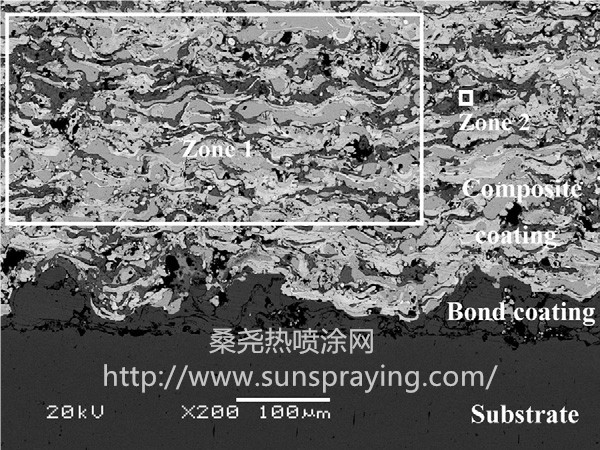

As a typical example of such coatings, thermally sprayed WC-based cermet coatings with advantageously combined hardness and toughness are widely used in aggressive environment where abrasive wear, erosive wear and other form of wear exist. However, thermally sprayed WC-based cermet coatings usually have large friction coefficient and cause severe wear of counterpart materials, which limits their tribological application. Recently, WC–(W,Cr)2C–Ni coating with superior high temperature oxidation resistance has been developed to replace traditional WC-based coatings [16]. Thermally sprayed WC–(W,Cr)2C–Ni coating, however, has a high friction coefficient at elevated temperature and still causes serious wear of counterpart materials. An atmospheric plasma spraying (APS) system is performed to prepare a series of WC–(W,Cr)2C–Ni/Ag/BaF2–CaF2 composite coatings by using the blended powders of different mass fractions of WC–(W,Cr)2C–Ni (matrix), Ag, and BaF2–CaF2 eutectics as the feedstock. The friction and wear behavior of as-sprayed WC–(W,Cr)2C–Ni/Ag/BaF2–CaF2 composite coatings is evaluated from room temperature to 600 ◦C in relation to the effect of solid lubricant dosage; and their wear mechanisms are discussed in relation to mechanical properties and worn surface features. Iintroducing appropriate amount of silver and fluoride eutectics contributes to effectively reduce the wear rate of the composite coatings at 200 and 400 ◦C. The optimized composite coating consists of 70 wt.% WC–(W,Cr)2C–Ni, 15 wt.% Ag and 15 wt.% BaF2/CaF2, and it has excellent friction and wear performance over a wide range of temperature.

本文由桑尧热喷涂网收集整理。本站文章未经允许不得转载;如欲转载请注明出处,北京桑尧科技开发有限公司网址:http://www.sunspraying.com/

|